Climate Change

- Strategy(Stance, Approach, Risks and Opportunities)

- Governance

- Indicators and Targets

- Major Initiatives

- Performance Data

(Stance, Approach, Risks and Opportunities)

Reducing Emissions throughout the Supply Chain

In line with the targets agreed at the 21st Conference of the United Nations Framework Convention on Climate Change (COP21), SEKISUI CHEMICAL Group has formulated a medium-term greenhouse gas (GHG) emission reduction plan.

In order to achieve the ambitious targets of the Paris Agreement, which are based on Science Based Targets (SBTs), we identify and disclose the risks and opportunities that climate-change have on business continuity based on scientific evidence. This is reflected in business planning and targets for reducing GHG emissions. We are working to reduce GHG emissions at every stage, from the procurement of raw materials through development to manufacturing, transportation, and use. We ascertain and disclose details of GHG emissions not only at our own business sites, but also throughout the entire supply chain, including suppliers of raw materials and the use of products sold.

- Out_E13

-

Note:Please refer to Policy Toward Mitigating and Addressing Climate Change.

Risks and Opportunities Posed by Climate Change to Our Businesses

SEKISUI CHEMICAL Group assesses the impact that climate change issues have on companies as well as the scale of impact that companies have on climate change, determines the importance of risks, and sets priorities to be addressed.

As far as the risks and opportunities associated with climate change issues are concerned, we assess the scale of economic impact on companies with respect to transition and physical risks. For risks and opportunities related to specific climate change issues, the scale, scope of impact, and other items are identified through scenario analyses based on the TCFD Guide.

We examine measures to mitigate the risks uncovered and consider the creation of new businesses by developing products and services for identified opportunities. Important risks along with possible countermeasures and strategies are reported to the Board of Directors through the Sustainability Committee. Important strategies are determined by the Board of Directors.We examine measures to mitigate the risks uncovered and consider the creation of new businesses by developing products and services for identified opportunities. Important risks along with possible countermeasures and strategies are reported to the Board of Directors through the Sustainability Committee. Important strategies are determined by the Board of Directors.

We believe that this kind of management will allow us to sustain our business into the future and remain a company that society demands to survive.

When considering the risks and opportunities of climate change associated with our business, we assess the impact of climate change mitigation and adaptation on transition and physical risks.

Examples include the following:

-

1.Housing Business

For example, the mandate for low-carbon products is one of the policy regulation risks that constitute a transition risk. By taking the lead in promoting such low-carbon products as ZEH housing, we are differentiating ourselves from the market, However, if the entire market works to address the low-carbon environment attributable to mandatory standards at an accelerated pace, we may not be able to differentiate our products over the long term. The risk then arises that our market share will decline. Notwithstanding the aforementioned, we believe that even if our market share declines, the market itself will expand, leading to opportunities for sales growth. Similarly, in the Housing Business, and from an acute physical risk perspective, the need for products that address infrastructure resilience and water risks will increase. Therefore, we believe that opportunities will emerge as demands on the resilient Town and Community Development Business increase. -

2.Example in the Plastic Molding and Processing Business

In the Innovative Mobility, Advanced Lifeline, and other Plastic Molding and Processing Business fields, we believe that transition risks of a market nature will have a significant impact. Changes in consumption behavior may induce opportunity losses due to the inability to recycle resources and use decarbonized incentives. On the other hand, we believe that visualizing resource recycling and decarbonization value will provide us with the opportunity to acquire incentives and expand sales.

Addressing Climate Change

SEKISUI CHEMICAL Group believes that it is important to earnestly confront all climate change risks and make every effort to keep the temperature rise to less than 1.5°C.

Based on SEKISUI Environment Sustainability Vision 2050 formulated in 2019, we will contribute to the resolution of environmental issues by reducing the environmental impact of our business activities.

Our goal is to eliminate GHG emissions from our own business activities by 2050. In addition to promoting the installation of solar power generation facilities for on-site consumption, we are increasing the Group’s renewable energy utilization ratio for the electricity purchased from outside sources. In this regard, we are targeting the goal of 100% by 2030.

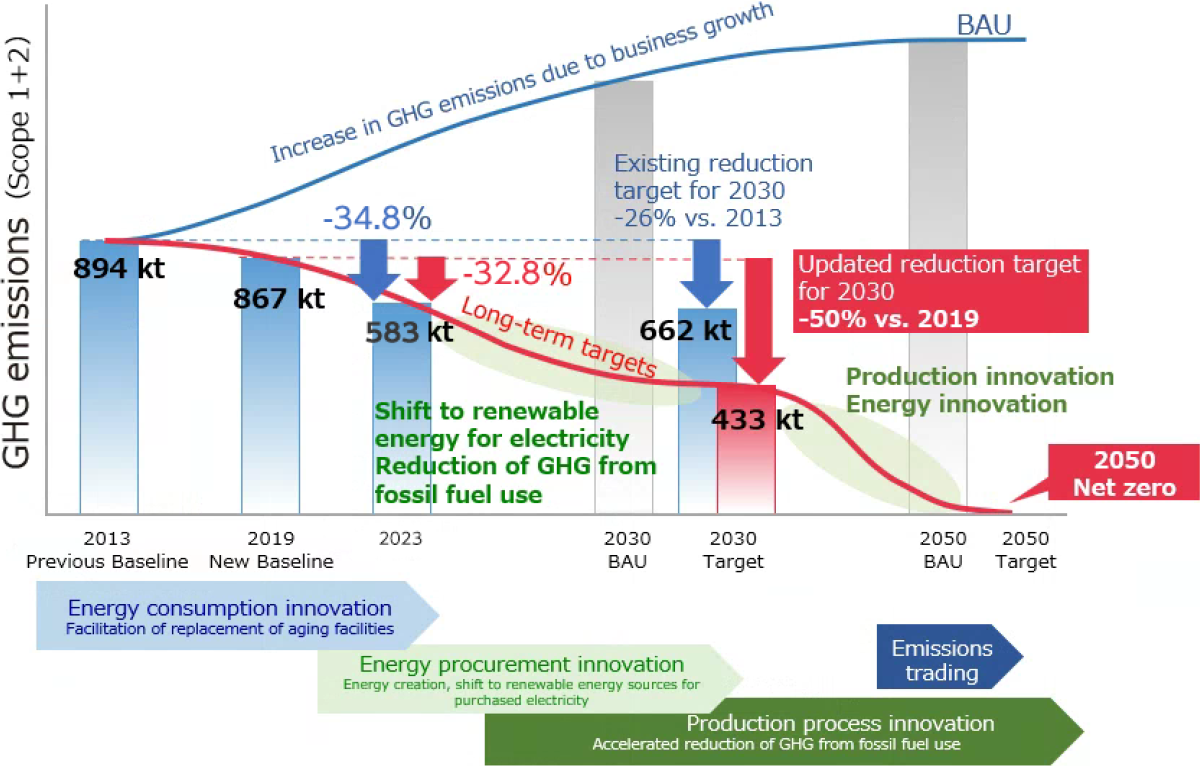

With an explicit roadmap in place, SEKISUI CHEMICAL Group had continued to promote GHG emission reduction activities with the goal of limiting the increase in global mean temperatures to no more than 2°C by 2030 until fiscal 2021. (We became the first chemical company in the world to obtain SBT certification in 2018). Having achieved reductions that exceeded our initial milestone, we set the new targets of 1.5°C from fiscal 2022 and a reduction of 50% in 2030 compared with 2019. In order to achieve these targets, we revised our GHG emissions roadmap for which we again obtained SBT certification. As a part of efforts to steadily reduce GHG emissions and achieve the 1.5°C target, we will take steps to consider and pursue fuel conversion and manufacturing innovation that will help secure reductions in GHGs from extremely difficult fuel sources (Scope 1) while further promoting the conversion of electric power to renewable energy.

Risk Management

As far as risk management is concerned, we have established an ERM system that in addition to identifying Group-wide major risks, shares and manages these risks within the Group. Among environmental issues, risks related to climate change issues are also assessed in an integrated manner, together with other risks that are expected to have a significant impact on management. Risks that effect the Group as a whole and each organization, including such environmental issues as climate change, resource recycling, water resources, and biodiversity, are shared and deliberated at Board of Directors, Sustainability Committee, in-house management, and subcommittee meetings.

Promotion System for Climate Change Issues

As far as external environmental issues that may pose certain management risks in connection with, for example, efforts to mitigate and address climate change are concerned, steps are taken to ascertain the magnitude of each risk and to consider as well as implement appropriate countermeasures under the supervision of the Board of Directors. In similar fashion to other environmental issues, our supervisory and executive systems for reducing the Group’s impact on climate change issues and expanding its contribution to the resolution of issues are based on our Environmental Management Promotion System. (For details see here). The Board of Directors has made the following final decisions on climate change issues.

- Policies and strategies to mitigate the impact of environmental issues, including climate change, and to expand contributions to solving them.

- The organization's plan to achieve a sustainable society, including the transition to a low-carbon economy (transition plan).

- Assessment of the impact of environmental issues, including climate change on management, and policies for addressing those issues.

Turning to major matters discussed and determined by the Board of Directors, the Sustainability Committee deliberates on policies and strategies in advance, based on conditions surrounding the Group as a whole regarding such environmental issues as climate change that have been discussed and summarized by the Environmental Subcommittee. In addition, based on the policies, strategies, and transition plans finalized by the Board of Directors, the Environmental Subcommittee discusses specific measures and goal setting while managing progress.

Targets

GHG

Aim: Decarbonization/zero GHG emissions

Indicator 1. GHG emission reduction rate

Current Medium-term Management Plan Target (final year: FY2025) -33% (compared with FY2019)

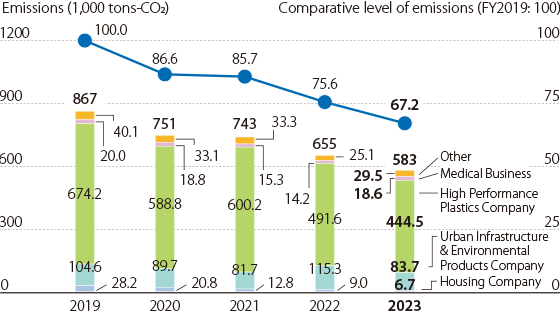

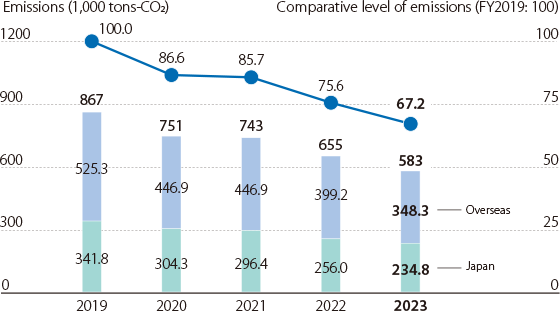

FY2023 Results -32.8% (compared with FY2019)

2030 Target -50% (compared with FY2019)

2050 Target -100%

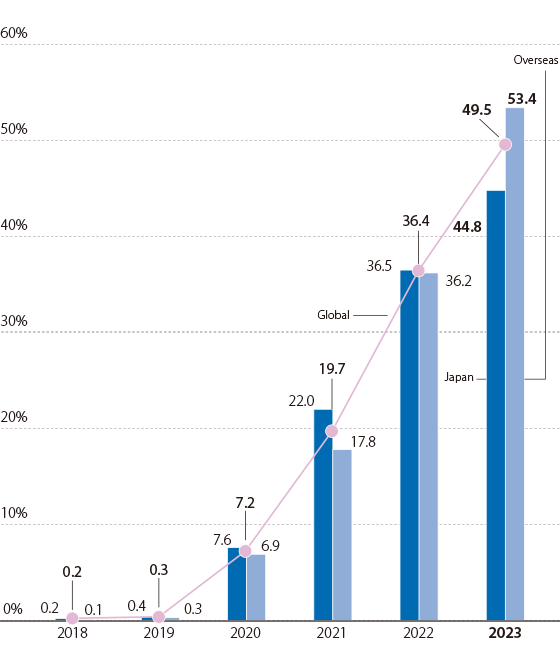

Indicator 2. Renewable energy ratio of purchased electricity

(including solar power generation for in-house use)

Current Medium-term Management Plan Target (final year: FY2025) 70%

FY2023 Results 49.5%

2030 Target 100%

2050 Target 100% Total power consumption including co-generation

Reduce energy usage volume

Aim: Improve energy efficiency and reduce energy expenses during production

Indicator: Reduction rate of energy consumption per unit of production

Current Medium-term Management Plan Target (final year: FY2025) -3% (compared with FY2022)

FY2023 Results +3.5% (compared with FY2022)

2030 Target ー

2050 Target ー

Addressing the Rising Costs Associated with Climate Change Strategies

SEKISUI CHEMICAL Group is working to significantly improve energy efficiency in its production processes in order to reduce the Group’s environmental impact. By transforming and improving production processes and continuously upgrading equipment, we are taking steps to visualize energy use and to reduce consumption.

Since fiscal 2020, we have been promoting the conversion of purchased power to renewable energy on a global basis. We are working to reduce electricity costs from a long-term perspective by introducing solar power generation facilities at our production sites through capital investment and consuming the power generated in-house.

Since fiscal 2023, we have also worked to innovate our production processes and consider ways to reduce fuel-derived greenhouse gases.

Product Development and Strategies Aimed at Solving Environmental Issues and Meeting the Changing Needs of the Market

SEKISUI CHEMICAL Group develops products that contribute to the resolution of issues related to the natural and social environments, and continues to disclose and disseminate details of specific results. Through these efforts, we are managing risks that arise from changes in market needs against the backdrop of such global issues as climate change. At the same time, we believe that this will be enable us to seize opportunities attributable to increased demand.

In particular, by quantifying as much as possible the size (degree of contribution) of each product's contribution to the resolution of issues, we believe that we can magnify the impact we create, which in turn will lead to opportunities to create markets that help solve global issues and further heighten the awareness of consumers.

In fiscal 2020, we established the MINASE INNOVATION CENTER (MIC) as an organization to promote open innovation with stakeholders. The goals here are to strengthen partnerships with stakeholders and to engage in activities to increase our contribution to solving issues through co-innovation (fusion) while accelerating solutions through early dissemination.

Through MIC, we are actively engaging in technology exchanges with startup companies that possess low-carbon technologies as well as materials and other technologies that contribute to resource conversion, and are initiating steps to accelerate the resolution of social issues.

Addressing the Deterioration in Operating and Working Conditions

If climate change worsens and the minimum and maximum temperatures become increasingly severe, people engaged in manufacturing and construction may not be able to work. SEKISUI CHEMICAL Group believes that it is also possible to minimize the impact of climate change by proposing construction and engineering plans that take into consideration the seasonality of each region.

Each divisional company and Group subsidiary has formulated a BCP tailored to its own circumstances as a means of mitigating the risk of a loss in operations and employment opportunities caused by natural disasters or other events.

Certification under the SBT* Initiative

SEKISUI CHEMICAL Group was the first company in the chemical sector to acquire SBT certification in 2018. The Group set a target of reducing GHG emissions by 26% by 2030 compared with the levels recorded in fiscal 2013. In order to achieve this goal, we have promoted energy consumption innovation, including the replacement of aging facilities, and such energy procurement innovation initiatives as the conversion of purchased electricity to renewable energy and the installation of solar power generation facilities for on-site consumption.

As a result, the ratio of renewable energy ratio to the Group’s total purchased electricity reached 49.5% in fiscal 2023. The rate of GHG emission reduction was 32.8% compared with fiscal 2019.

As climate change countermeasures become an even more urgent social issue, we have decided to increase our 2030 GHG emission reduction rate target by pursuing the technically difficult task of reducing fuel-derived GHG emissions ahead of schedule. This includes the use of electric power at facilities that consume fuel, switching to low-carbon fuels, and innovating production processes.

With the aforementioned in mind, we updated our SBT certification to the 1.5°C target in March 2023.

- Out_E14

| Previous Targets | Updated Targets | Means of Achieving Updated Targets | |

|---|---|---|---|

| Scope1+2 | Base year: 2013 Target year: 2030 Reduction rate: 26% (2.0°C target) |

Base year: 2019 Target year: 2030 (unchanged) Reduction rate: 50% (1.5°C target) |

Adopt renewable energy for conventional purchased electricity, and also pursue in advance the shift to low-carbon fuels, electrification, and production innovation to reduce fuel-derived GHGs |

| Scope3 | Base year: 2016 Target year: 2030 Reduction rate: 27% |

Base year: 2019 Target year: 2030 (unchanged) Reduction rate: 30% |

Add resource recycling measures (conversion to non-fossil raw materials, increased use of recycled materials, and recycling of waste) to promote reductions in categories 1, 5, and 12 |

<Progress in FY2023>

Scope 1+2: Reduced greenhouse gas emissions by 32.8% compared with FY2019

Scope 3: Reduced greenhouse gas emissions by 8.8% compared with FY2019

In the future, we will continue to recognize our responsibility as a driving force within the industry and strive to lead and implore society as a whole to deal with climate change.

-

* SBT:Science Based Targets. The adoption of the Paris Agreement led to the proposal of such joint initiatives as the United Nations Global Compact. SBT initiatives certify that the GHG reduction targets set by companies are science based targets (SBT) that contribute to long-term measures aimed at combating climate change.

Promoting the Shift to Renewable Energy for Electric Power

We recognize that climate change is not only a major social issue, but also a major risk factor for the Group. In August 2020, we joined RE100, an international initiative which aims to procure the energy consumed in business activities entirely from renewable energy sources, in order to accelerate efforts that contribute to solving this issue throughout society. In the future, we will promote activities in cooperation with member companies and organizations.

We will promote thoroughgoing energy conservation measures and the shift to renewable energy in a bid to achieve zero GHG emissions from our business activities by 2050 as well as the GHG emissions target certified by the SBT Initiative by 2030.

Moreover, we will shift to renewable energy for all of the electric power we purchase from outside sources by 2030, and ensure that all electric power is derived from renewable energy sources, including co-generation systems, by 2050.

Environmental Management Across the Supply Chain

When we begin or continue to undertake business with our suppliers, we ask them to establish environmental management systems that comply with ISO 14001 and t to reduce their environmental impact. In particular, with regard to the issue of climate change, we are taking steps to ascertain the progress made in setting and tackling reduction targets.

Furthermore, we monitor the volume of raw materials used by the Group as well as the impact on the environment.

With regard to wood, which is considered to have a significant impact on biodiversity issues, we have formulated procurement guidelines* specific to wood in an effort to procure all of our needs from sustainable forests. Looking ahead, we will identify risks and conduct due diligence to reduce risks through supplier surveys.

- For details, please refer to the Timber Procurement Policy

Addressing Climate Change Challenges

Compatibility with Scope 3*

The volume of GHG emissions that falls under the Scope 3 category is substantial at the raw material procurement and product use stages. Based on this, we are stepping up efforts to reach out to raw material suppliers. We recognize that the reason for the large volume of emissions at the raw material procurement stage is the nature of our business as a chemical manufacturer.

In order to reduce GHG emissions when procuring raw materials, we reviewed our selection criteria for new materials. From a raw material perspective, we are requesting the presentation of GHG emissions data during raw material manufacture from more than 10 manufacturing companies, while promoting efforts to reduce greenhouse gases under Scope 3 in the future for the four major resins that are purchased in large volumes and have high levels of GHG emissions In this manner, we are working to reduce Scope 3 GHG emissions in the future.

While the Group obtains only a portion of the total data from suppliers, by using this data we are able to grasp the volume of GHG emissions over the entire lifecycle.

Drawing on the IDEA database, we are studying measures to reduce GHG emissions and promoting reduction activities across the supply chain.

In addition, we have confirmed with suppliers the possibility of providing lower-carbon biomass-derived raw materials and recycled materials, and have begun to consider alternatives.

In specific terms, we will switch to non-fossil sources for resin materials, which account for 50% of purchased products and services (Category 1), and expand the use of recycled materials. This will help reduce GHG emissions from the disposal of products sold (Category 12).

Moreover, we will promote the recycling of waste plastics and work to reduce the amount of waste (Category 5) generated by our operations.

Meanwhile, GHG emissions at the product-use stage are largely attributable to the substantial volumes of greenhouse gases emitted as a result of the energy consumed by the houses we sell.

Regarding the use of products sold (Category 11), higher sales of ZEH homes with Sekisui Heim's energy-saving performance and large-capacity photovoltaic/large-capacity storage batteries have contributed significantly to reducing GHG emissions. We will continue to expand sales of ZEH homes, which will lead to further reductions.

- Scope 3: Other indirect emissions for the portion other than direct emissions at the Company (Scope 1) and indirect emissions to the Company (Scope 2).

Promoting the Use of Renewable Energy

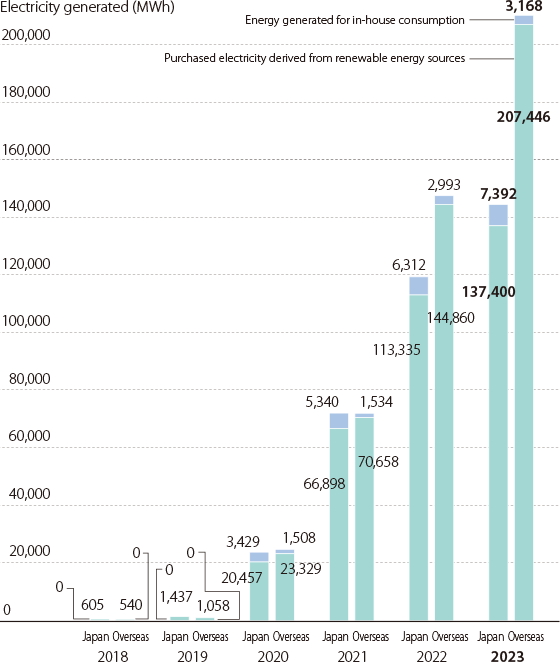

SEKISUI CHEMICAL Group has been promoting the use of renewable energy by installing solar power generation systems at its production sites in Japan and overseas.

Since fiscal 2020, we have also actively promoted the switch to renewable energy sources for electricity purchased. As of the end of March, 2023, 41 business sites in Japan and overseas have switched to renewable energy sources for all of their electricity purchased. Electricity consumption derived from renewable energy sources in fiscal 2023 was 355GWh, which is equivalent to 49.5% of all electricity purchased (including solar power generation for in-house use) and 44.2% of total electricity consumption, including electricity generated in-house by co-generation systems.

In fiscal 2023, the following 5 business sites newly installed solar power generation systems for in-house use, bringing the total number of business sites to 20.

- SEKISUI POLYMATECH (THAILAND)

- Sekisui Heim Industry Co., Ltd. Tokyo Site

- SEKISUI YOUNGBO HPP (WUXI) CO., LTD.

- Sekisui LB Tec Co., Ltd.

- Sekisui Soflan Wiz CO., LTD. Astugi Plant

| Solar Power Generation Facilities Producing Electricity for On-site Use | |

|---|---|

| Japan | Tohoku Sekisui Heim Industry Co., Ltd. |

| Chushikoku Sekisui Heim Industry Co., Ltd. | |

| Kyushu Sekisui Heim Industry Co., Ltd. | |

| Sekisui Heim Industry Co., Ltd. Kanto Site | |

| Yamanashi Sekisui Co., Ltd. | |

| SEKISUI SEIKEI, LTD. Kanto Plant | |

| Sekisui Medical Co., Ltd. Tsukuba Plant | |

| SEKISUI CHEMICAL Co., Ltd. Taga Plant | |

| SEKISUI CHEMICAL Co., Ltd. Shiga-Ritto Plant | |

| USA | SEKISUI S-LEC AMERICA, LLC. |

| Netherlands | SEKISUI S-LEC B.V. Film Plant |

| Thailand | SEKISUI S-LEC (THAILAND) CO., LTD. |

| SEKISUI-SCG INDUSTRY CO., LTD. | |

| China | Sekisui Medical Technology (China) Ltd. |

| Sekisui (Wuxi) Plastics Technology Co., Ltd. | |

| Facilities for which 100% of electricity is derived from renewable energy sources | |

|---|---|

| Japan | SEKISUI CHEMICAL Co., Ltd. Gunma Plant |

| SEKISUI CHEMICAL Co., Ltd. Taga Plant | |

| SEKISUI CHEMICAL Co., Ltd. Research and Development Institute | |

| SEKISUI CHEMICAL Co., Ltd. Tsukuba Site | |

| SEKISUI CHEMICAL Co., Ltd. Tokyo Headquarters | |

| SEKISUI CHEMICAL Co., Ltd. Osaka Headquarters | |

| Hokkaido Sekisui Heim Industry Co., Ltd. | |

| Tohoku Sekisui Heim Industry Co., Ltd. | |

| Sekisui Heim Industry Co., Ltd. Kanto Site | |

| Sekisui Heim Industry Co., Ltd. Tokyo Site | |

| Sekisui Heim Industry Co., Ltd. Chubu Site | |

| Sekisui Heim Industry Co., Ltd. Kinki Site | |

| Chushikoku Sekisui Heim Industry Co., Ltd. | |

| Kyushu Sekisui Heim Industry Co., Ltd. | |

| Sekisui Board Co., Ltd. Minakuchi Plant | |

| Sekisui Board Co., Ltd. Gunma Plant | |

| Yamanashi Sekisui Co., Ltd. | |

| Sekisui Medical Co., Ltd. Tsukuba Plant | |

| Sekisui Medical Co., Ltd. Ami Site | |

| Sekisui Medical Co., Ltd. Drug Development Solutions Center | |

| Sekisui Soflan Wiz CO., LTD. Iwaki Plant | |

| Chiba Sekisui Industry Co., Ltd. | |

| Netherlands | SEKISUI S-LEC B.V. Film Plant |

| SEKISUI S-LEC B.V. Resin Plant | |

| SEKISUI ALVEO B.V. | |

| SEKISUI POLYMATECH EUROPE B.V. | |

| SEKISUI ESLON B.V. | |

| Germany | SEKISUI ALVEO BS GmbH |

| Spain | SEKISUI SPECIALTY CHEMICALS EUROPE S.L. |

| UK | SEKISUI DIAGNOSTICS (UK) LIMITED |

| USA | SEKISUI S-LEC AMERICA, LLC. |

| China | SEKISUI S-LEC (SUZHOU) CO., LTD. |

| SEKISUI (WUXI) PLASTICS TECHNOLOGY CO., LTD. | |

| SEKISUI YOUNGBO HPP (WUXI) CO., LTD. | |

| SEKISUI POLYMATECH CO., LTD. Shanghai Plant | |

| Thailand | SEKISUI S-LEC (THAILAND) CO., LTD. |

| SEKISUI POLYMATECH (THAILAND) CO., LTD. | |

| SEKISUI SPECIALTY CHEMICALS (THAILAND) CO., LTD. | |

| THAI SEKISUI FOAM CO., LTD. | |

| S AND L SPECIALTY POLYMERS CO., LTD. | |

| Singapore | VEREDUS LABORATORIES PTE. LTD. |

Environmental Activities at Offices in line with the Group's Environmental Management System (EMS)

SEKISUI CHEMICAL Group is promoting environmental activities in its offices that are in line with the Group’s Environmental Management System (EMS). We are implementing a variety of environmental activities at our offices nationwide, including such energy-saving activities as turning off lights during lunch breaks and reducing paper consumption.

Head Office Building Renewal and New Energy Creation Products

SEKISUI CHEMICAL Group has continued to work with Kanden Realty & Development Co., Ltd. to renovate its Osaka Head Office (Dojima Kanden Building), which is 50 years old, since 2023. This building was the first office building over 30 years’ old to receive the highest S-rank "CASBEE Smart Wellness Office Certification".*

- The "CASBEE Smart Wellness Office Certification" System is a system that evaluates the health, comfort, and intellectual productivity of building users as well as the performance of buildings in terms of their energy-saving environment, safety, and security from multiple perspectives.

In renovating the building, steps were taken to utilize Low-E double glazing, which improves indoor comfort while reducing air conditioning power consumption, thanks to its high thermal insulation and solar radiation shielding properties. We recognize that the renewal and continued use of aging buildings is not a conventional scrap and build approach, but a concept of building use that is critical to a resource-recycling society. Improving the durability of buildings and using them for a long time can save resources and reduce waste, reduce the amount of energy needed to manufacture building materials, and in turn, reduce GHG emissions throughout the lifecycle of buildings. In addition, more than 20 of the Group's products that contribute to the safety, durability, and environmental performance of buildings and infrastructure were used in the renewal. In October 2023, film-type perovskite solar cells, which are currently under development, were installed on the exterior walls of the building. This is the first such case of exterior wall installation in Japan.

- Out_E87

Conceptual diagram of the Group’s Osaka headquarters after completion of renewal work

Contributing to Carbon Reduction and Decarbonization through Our Businesses

SEKISUI CHEMICAL Group will accelerate efforts to help realize a decarbonized society in 2050 through its business activities. To this end, we are promoting the creation of Products to Enhance Sustainability and the expansion of related markets through an internal system.

As far as the need to address climate change is concerned, we are focusing on products not only from a mitigation, but also an adaptation perspective in a bid to expand markets.

Specific examples are listed as follows.

[Examples of Products That Contribute to Climate Change Mitigation]

-

<Housing>Products and services that use renewable electricity and support energy-efficient lifestyles

-

Example)ZEH housing (net-zero energy house)

-

-

<Innovative Mobility>Lightweight and highly functional products that reduce energy consumption during transportation and shipping

-

Example)Interlayer films for automotive laminated glass (S-LEC®) that boasts thermal and acoustic insulation functions

Sheet materials used in airplanes, trains, etc. (SEKISUI KYDEX product)

-

-

<Electronics>Materials essential for energy-efficient products, products that contribute to improving the durability and performance of related components, which are becoming increasingly important with the development of 5G connectivity, etc.

-

Example)Heat release materials that help mitigate issues caused by overheating circuit boards (Sekisui Polymatech Co., Ltd. product)

Materials used in energy-efficient equipment (Micropearl). functional tape

-

-

<Infrastructure>Products that reduce GHG emissions throughout their life cycles by swapping out conventional raw materials, production, and molding methods that extend their useful lives, etc.

-

Example)Plastic piping in factories through which chemicals and other materials flow. Compared to mainstream metal piping, plastic piping reduces GHG emissions over its life cycle.

-

[Examples of Products That Contribute to Climate Change Adaptation]

-

<Building and Civil Engineering>Products that contribute to the management of disasters that are increasing and becoming more severe due to the progress of climate change

-

Example)Products that enable temporary storage of rainwater in the event of torrential rain

-

[[Initiatives in Collaboration with Other Companies] Carbon recycling technology project in partnership with ArcelorMittal S.A.

In order to reduce our reliance on fossil fuels and contribute to decarbonization during steelmaking, SEKISUI CHEMICAL and ArcelorMittal entered into a partnership on projects to recover and reuse CO2 emitted during the steelmaking process. Through this project, we will work to develop technologies for separating, recovering, and reusing CO2 from the gases emitted during the steelmaking process in the steel industry. Key to this work is SEKISUI CHEMICAL’s innovative technology that converts CO2 into carbon monoxide at higher yield.

[Progress against Commitments] Increasing the market penetration rate of ZEH housing

We are committed to increasing the percentage of homes sold that use ZEH in order to reduce the use of fossil-based energy by our customers in the Sekisui Heim homes. In fiscal 2023, the ratio of new detached net-zero energy houses (ZEH) (actual results calculated based on ZEH builder's reporting methods) was 96%, of which 89% was for ZEH, which has the highest rate of energy savings among the three categories defined in the national ZEH.

The cumulative number of houses equipped with storage batteries (energy self-sufficient houses), which we are proposing along with houses with ZEH specifications, is also increasing, and the storage cell installation rate for new detached homes has grown to 87%*.

- Based on Company data, the percentage of storage batteries (including VtoH) used on a contract basis from April 2023 to March 2024. Figures are rounded to the nearest whole number.

Activities in Related Initiatives

Toward Climate Change Mitigation

SEKISUI CHEMICAL Group is collaborating with other companies and organizations in an effort to achieve its long-term goals and ultimately to contribute to the resolution of climate change issues. Through collaboration, we hope to expand our contribution and achieve milestones ahead of schedule.

The Group aims to achieve the goals set out in the Paris Agreement, namely the 1.5°C target, and to ensure carbon neutrality. We participate in and register with various initiatives, forums, and other organizations after confirming that their founding intentions, direction of initiatives, goals, etc. are consistent with the will and direction of the Group. To continue this participation, we check each year to see if there are any discrepancies in the direction we are taking, and to then make the necessary decisions. If we determine that the direction differs, we will take steps to withdraw.

The Japan Climate Change Initiative (JCI)

-

Significance/Objectives・・・・Joining the front line from Japan in the global push toward decarbonization in order to mitigate climate change.

-

Activities・・・・・・・・・・・・・・・・In order to drive social change and steer toward decarbonization, steps are being taken under the JCI to promote the dissemination of information and exchange of views from companies, local governments, and NGO that are actively engaged in climate-change measures, and to advance the declaration of goals and activities aimed at achieving objectives.

-

Our role・・・・・・・・・・・・・・・・・・We share the latest information on our efforts and use that information to consider measures.

RE100

-

Significance/Objectives・・・・Aim for companies to obtain 100% of the electricity used by their own operations from renewable energy sources.

-

Activities・・・・・・・・・・・・・・・・・Motivated companies that have made the declaration work together to promote communication and activities that have an impact on society.

-

Our role・・・・・・・・・・・・・・・・・・By declaring our commitment to shift to renewable energy, we are contributing to the widespread use of renewable energy in society.

JAPAN CLIMATE LEADERS’ PARTNERSHIP (JCLP)

-

Significance/Objectives・・・Aim to realize a rapid transition to a decarbonized society and achieve the 1.5°C target to avert a climate crisis.

-

Activities・・・・・・・・・・・・・・・・・Leading Japan in five pillars to achieve policy changes

Pursuing policy engagement, promoting decarbonization within companies, providing solutions to decarbonize society, communicating with society, and cooperating with global networks -

Our role・・・・・・・・・・・・・・・・・・Decarbonize the Company and society by making a decarbonization declaration, transitioning to a decarbonized business model, and pursuing corporate collaboration to promote internal decarbonization mainly within supply chains.

GX League

-

Significance/Objectives・・・・Aim to accelerate corporate collaboration in an effort to address the challenges associated with the transition to carbon neutrality in Japan.

-

Activities・・・・・・・・・・・・・・・・・Participating companies that have endorsed the objectives of the GX League are working together and are preparing to promote initiatives to solve various issues.

-

Our role・・・・・・・・・・・・・・・・・・We will consider participating in and promoting initiatives to resolve various issues in the future.

-

Note:In line with a change in the control of certain businesses in the UIEP and HPP companies implemented from October 2022, the data of both companies for FY2022 is collated as if the change in control had been initiated from the beginning of FY2022.

- Out_E21

- Out_E22

-

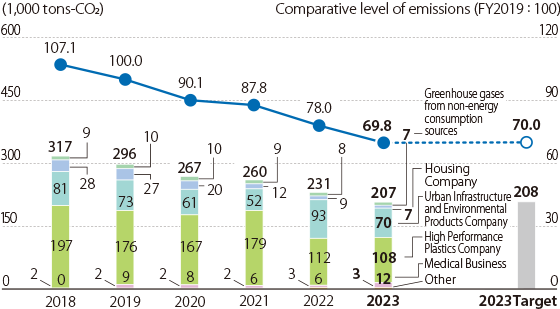

Scope1+2 (By Divisional Company)

-

Note 1:Some past figures have been revised due to improvements in precision.

-

Note 2:Data after deducting 64 thousand tons of CO2 equivalent to non-fossil certificates.

-

-

Scope1+2 (By Japan and overseas)

-

Note 1:Some past figures have been revised due to improvements in precision.

-

Note 2:Data after deducting 64 thousand tons of CO2 equivalent to non-fossil certificates.

-

- Out_E23

- Out_E24

-

Greenhouse Gas (GHG) Emissions during Manufacturing / Japan

-

Note:Some past figures have been revised due to improvements in precision.

-

-

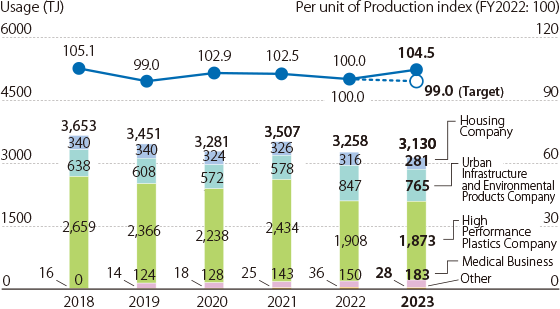

nergy Use and per Unit of Production* (Index) during Manufacturing / Japan

- Energy consumption per unit of production weight

-

Note:Some past figures have been revised due to improvements in precision.

- Out_E25

- Out_E26

-

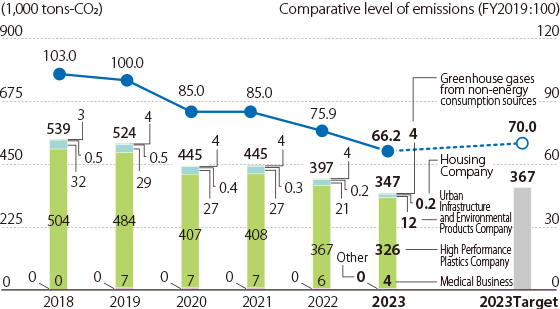

Greenhouse Gas (GHG) Emissions during Manufacturing / Overseas

-

Note:Data after deducting the equivalent non-fossil certificate of 64 thousand tons of CO2.

-

-

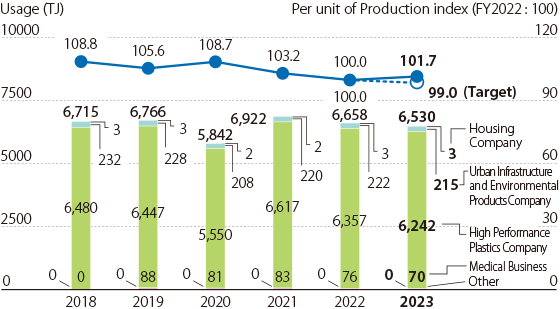

Energy Use and per Unit of Production* (Index) during Manufacturing / Overseas

- Energy consumption per unit of production weight

- Out_E27

- Out_E28

-

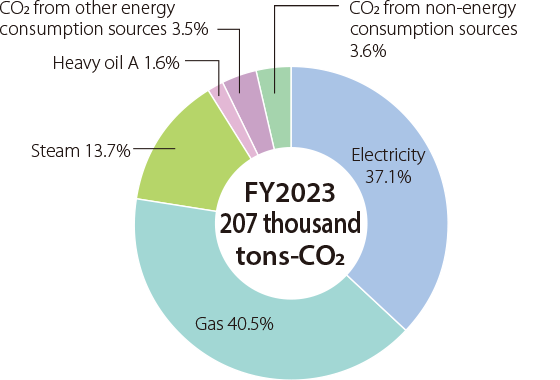

Breakdown of Greenhouse Gas (GHG) Emissions during Manufacturing / Japan

-

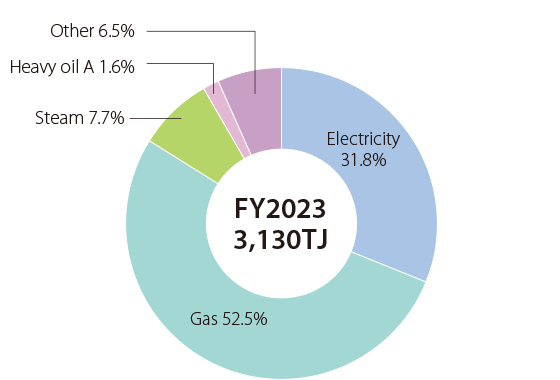

Breakdown of Energy Use during Manufacturing / Japan

- Out_E29

- Out_E30

-

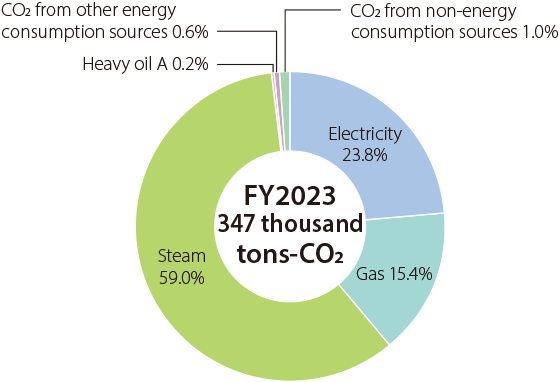

Breakdown of Greenhouse Gas (GHG) Emissions during Manufacturing / Overseas

-

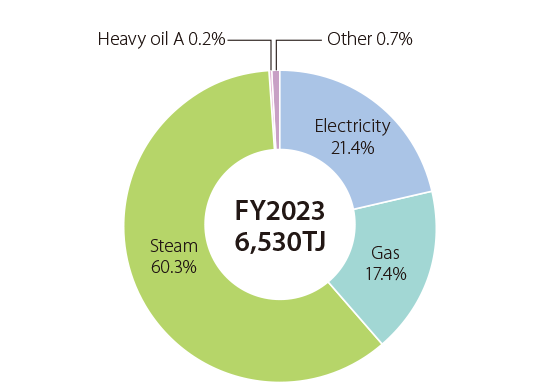

Breakdown of Energy Use during Manufacturing / Overseas

- Out_E31

- Out_E32

-

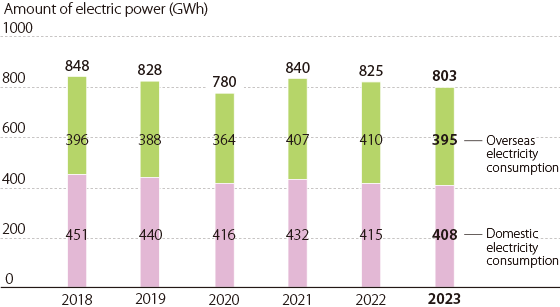

Electricity Consumption in Japan and Overseas

-

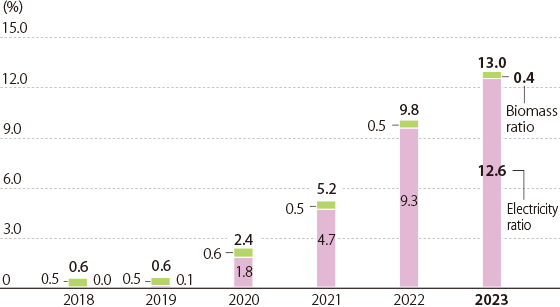

Ratio of Renewable Energy to Total Energy Consumption /

Electricity, Biomass Boilers

-

Note:Some past figures have been revised due to improvements in precision.

-

- Out_E33

- Out_E34

-

Energy generated for in-house consumption, amount of

purchased electricity derived from renewable energy sources / Japan and overseas

Note: excluding co-generation

-

Ratio of electricity derived from renewable energy sources / Japan and overseas

Note: excluding co-generation

-

Note:Some past figures have been revised due to improvements in precision.

-

| Indicator | Calculation Method |

|---|---|

| Greenhouse Gas Emissions | GHG emissions = Σ[fuel use, purchased electricity, purchased steam × CO2 emissions coefficient] + greenhouse gas emissions from non-energy consumption sources Greenhouse gas emissions from non-energy consumption sources = CO2 emissions not arising from energy consumption* + Σ[emissions of non-CO2 greenhouse gases × global warming potential] *Includes CO2 emissions from burning of non-fuel gases based on the Act on Promotion of Global Warming Countermeasures, both inside Japan and overseas [CO2 Emissions Coefficient]

|

| Energy Use | Energy use = Σ[amount of fuel used, amount of electricity purchased, amount of solar power generation for in-house use, and amount of steam purchased x unit calorific value] [Unit Calorific Value]

Fuel, Purchased Steam: Based on the Act on Rationalization of Energy Use and Shift to Non-fossil Energy |

- Out_E35

- Out_E36

-

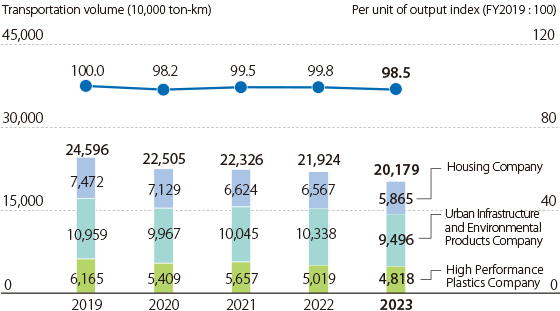

Transportation Volumes and Energy per Unit of Transportation (Index)* / Japan

- Energy consumption per unit of transportation volume

-

CO2 Emissions during the Transportation Stage / Japan

| Indicator | Calculation Method |

|---|---|

| CO2 Emissions during the Transportation Stage | The calculation is made by combining the fuel consumption method (transport of housing units, etc.) and the improved ton-kilometer method (other than transport of housing units, etc.) CO2 emissions = Σ[fuel use × CO2 emissions coefficient] + Σ[amount transported (metric tons) × distance transported (km) × fuel use per unit of transportation × CO2 emissions coefficient] Fuel use per unit of transportation is the value used in the reporting system for specified freight carriers under the Act on the Rational Use of Energy Major domestic distribution (shipment of products) is covered |

- Out_E37

-

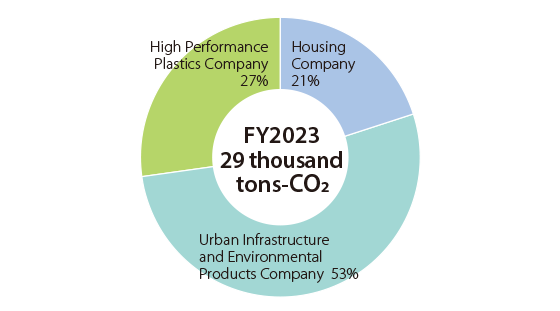

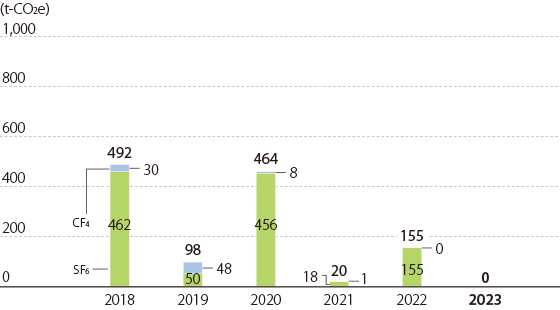

Emissions of Non-CO2 Greenhouse Gases (Global Production, Laboratories)

-

Note:Zero emissions due to improvements in working method with respect to the recovery of SF6 from fiscal 2023.

-

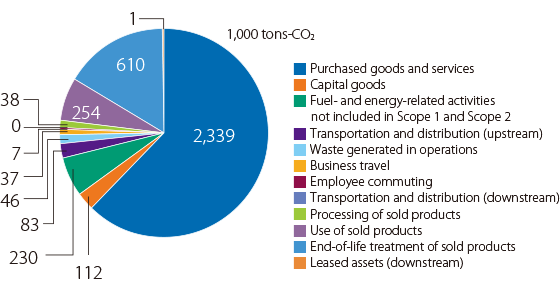

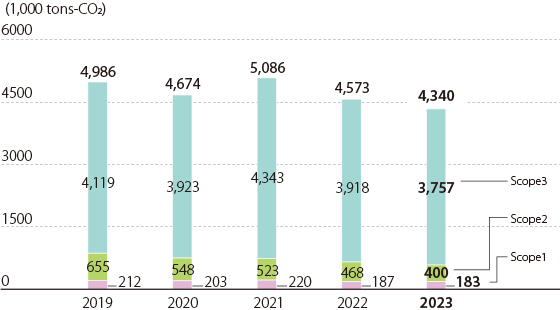

Greenhouse Gas Emissions throughout Our Supply Chain (Scope 3)

| Category | ||||||

|---|---|---|---|---|---|---|

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | ||

| Upstream | Purchased goods and services | 2,352 | 2,282 | 2,445 | 2,205 | 2,339 |

| Capital goods | 96 | 80 | 74 | 113 | 112 | |

| Fuel-and energy related activities not included in Scope 1 and Scope 2 | 127 | 198 | 226 | 220 | 230 | |

| Transportation and Distribution (Upstream) (Transportation of major raw materials) | 95 | 86 | 93 | 77 | 83 | |

| Waste generated in operations | 44 | 37 | 41 | 44 | 46 | |

| Business travel | 24 | 7 | 6 | 23 | 37 | |

| Employee commuting | 6 | 5 | 4 | 9 | 7 | |

| Downstream | Transportation and Distribution (Downstream) (Transportation of products) | 0 | 0 | 0 | 0 | 0 |

| Processing of sold products | 45 | 39 | 41 | 41 | 38 | |

| Use of sold products | 772 | 708 | 810 | 625 | 254 | |

| End-of-life treatment of sold products | 558 | 481 | 601 | 559 | 610 | |

| Leased assets (downstream) | 2 | 1 | 1 | 2 | 1 | |

| Total(upstream / downstream) | 4,119 | 3,923 | 4,343 | 3,918 | 3,757 | |

- Out_E39

- Out_E40

Greenhouse Gas Emissions throughout Our Supply Chain as a Whole (Classified by Scope)

-

Note:Some past figures have been revised due to improvements in precision.

| Indicator | Calculation Method | |

|---|---|---|

| Greenhouse Gas Emissions throughout Our Supply Chain | Purchased Goods and Services | CO2 emissions = ∑[(amount of major raw materials used (excluding substances subject to regulation by the PRTR Law) as listed in Material Balance section of this report + estimated values for other raw materials) × emission coefficient (Inventory Database for Environmental Analysis (IDEA) Ver.3.1 (the world’s largest GHG emissions database developed by the National Institute of Advanced Industrial Science and Technology (IDEA v.3.1))] Calculated using MiLCA v.3.1 software from LCA Expert Center Co., Ltd. that incorporates IDEA v.3.1. The Group has reflected the actual GHG emissions of its raw material suppliers with regard to four principal resins (PP, PE, PVC and PVA) from FY2018. |

| Capital Goods | CO2 emissions = ∑[(amount of spending on capital expenditures authorized for the given fiscal year for buildings, structures, mechanical equipment, and transport vehicles) × emissions coefficient (per unit emissions database for calculating organizational greenhouse gas emissions, etc., arising from supply chains (Ver. 3.3) (Ministry of the Environment and Ministry of the Economy, Trade and Industry))] | |

| Fuel- and Energy-related Activities not Included in Scope 1 and Scope 2 | CO2 emissions = ∑[(fuel use, amount of purchased electricity, and amount of purchased steam) × emissions coefficient] The emissions coefficients used are as follows. For fuel IDEA v.3.1 For purchased electricity and steam, per unit emission database for calculating greenhouse gas emissions by organizations, etc., arising from supply chains (Ver. 3.3) (Ministry of the Environment and Ministry of the Economy, Trade and Industry). Applicable to production sites, laboratories, and offices both inside Japan and overseas. |

|

| Transportation and Distribution (Upstream) (Transportation of major raw materials) | CO2 emissions = ∑[amount of major raw materials used (excluding substances subject to regulation by the PRTR Law) as listed in the Material Balance section of this report × transport distance × emission coefficient (IDEA v.3.1)] (Calculated assuming that the transport distance was uniformly 200 km) |

|

| Transportation and Distribution (Downstream) (Transportation of products) | The calculation is made by combining the fuel consumption method (transport of housing units, etc.) and the improved ton-kilometer method (other than transport of housing unit, etc.) CO2 emissions = Σ[fuel use × CO2 emissions coefficient] + Σ[amount transported (metric tons) × distance transported (km) × fuel use per unit of output × CO2 emissions coefficient (value used in the reporting system for specified freight carriers under the Act on the Rational Use of Energy)] (Estimates used for overseas) Covers shipments of products by Group companies in Japan and overseas. |

|

| Waste Generated in Operations | CO2 emissions = ∑[amount of waste materials generated (by type) × emission coefficient (IDEA v.3.1)] Scope: Major production sites and research facilities in Japan and overseas. |

|

| Business Travel | CO2 emissions = Σ[transportation costs by method of transport × emissions coefficient (per unit emissions database for calculating organizational greenhouse gas emissions, etc., arising from supply chains (Ver. 3.3) (Ministry of the Environment and Ministry of the Economy, Trade and Industry))] (Includes estimates of transportation costs for Group companies) Group companies in Japan and overseas all covered. |

|

| Employee Commuting | CO2 emissions = Σ[amount spent on commuting allowance × emissions coefficient (per unit emissions database for calculating organizational greenhouse gas emissions, etc., arising from supply chains (Ver. 3.3) (Ministry of the Environment and Ministry of the Economy, Trade and Industry)] (Calculated based on the assumption that all commuting is done by passenger train) (Group company commuting costs include estimates) Group companies in Japan and overseas all covered. |

|

| Processing of Sold Products | CO2 emissions = Σ[production volume of relevant products × emission coefficient at the time of processing the relevant products (IDEA v.3.1)] Covers products for the automotive industry by Group companies in Japan and overseas. |

|

| Use of Sold Products | CO2 emissions = Σ[number of structures sold as housing during the relevant fiscal year × amount of electricity purchased from power companies throughout a year × 60 years × electricity-based emissions coefficient], including the effect of the solar power generation system. The amount of electricity purchased from power companies throughout a year is based on the Electricity Income and Expenditure Home Survey of Houses with Built-In Solar Power Generation Systems (2023). The electricity-based emissions coefficient employed is the emissions coefficient from the FY2023 report produced by the Act on Promotion of Global Warming Countermeasures reporting system (alternate value), equal to 0.441 metric tons-CO2 /MWh. The calculation is performed under the assumption that housing will be used for 60 years. Housing sold within Japan for the fiscal year relevant to the calculation is covered. Up to and including FY2017, the Group calculated the amount of greenhouse gas reduction achieved through solar power generation as the amount of reduced environmental impact. From FY2018, however, we are also calculating the effect of reduction in energy used in residences built to zero energy house (ZEH) specifications. |

|

| End-of-life Treatment of Sold Products | CO2 emissions = Σ[amount of major raw materials used in the products sold during the relevant fiscal year × emission coefficient (IDEA v.3.1)] The calculation assumes that products sold during a given fiscal year are disposed of during the same fiscal year. |

|

| Leased Assets (Downstream) | Calculated for construction work carried out using machinery leased by SEKISUI CHEMICAL. CO2 emissions = Σ[relevant installation units × fuel usage per unit × CO2 emissions coefficient (emissions coefficient determined based on a system of greenhouse gas emission calculations, reports, and official disclosures)] |

|