Climate Change

Efforts to Reduce Greenhouse Gas Emissions throughout the Supply Chain

Reducing Emissions throughout the Supply Chain

SEKISUI CHEMICAL Group has formulated a medium-term greenhouse gas emission reduction plan in line with targets established at COP21 (the 21st Conference of the United Nations Framework Convention on Climate Change).

We are identifying and disclosing the effects in terms of risks and opportunities that climate change will have on business continuity in line with science-based scenarios aimed at the achievement of the ambitious goals of the Paris Agreement, which are based on Science Based Targets (SBT). Moreover, we reflect these factors into our business plans and emission reduction targets. Concerning emissions, SEKISUI CHEMICAL is engaged in reducing greenhouse gas emissions at every stage, from the procurement of raw materials to development, manufacturing, transport, and use. We monitor these emissions throughout the entire supply chain. This does not only includes our own business sites, but also raw material suppliers as well as the use of our products after being sold. Steps are then taken to publicly disclose the findings.

- 11-31

Addressing Climate Change

SEKISUI CHEMICAL Group believes that it is important to earnestly confront all climate change risks and make every effort to keep the temperature rise to less than 1.5°C. Under the SEKISUI Environment Sustainability Vision 2050 that was formulated in 2019, we are trying to contribute to solving environmental issues by reducing the environmental impact of our business activities. We have set a target of zero GHG emissions due to our business activities by 2050. Moreover, we are advancing the introduction of solar power equipment to generate electricity for use at our own business sites in which it was installed, increasing our utilization ratio for renewable energy from externally purchased electricity and have set a new target value of 100% by 2030. We focused on initiatives to achieve a 26% reduction in GHG emissions by 2030, to which we committed ourselves under the SBT initiative. As a result, we expect to reach this target earlier than planned and therefore have begun considering raising the 2030 reduction target.

Risks and Opportunities Posed by Climate Change to Our Businesses

We also strive to understand the risks and opportunities that climate change presents to the operations of SEKISUI CHEMICAL Group, in terms of their magnitude, scope of impact, and other matters through scenario analysis conducted based on the TCFD Guide.

SEKISUI CHEMICAL Group examines measures to mitigate identified risks and considers the creation of new businesses by developing products and services for identified opportunities. Significant risks along with possible countermeasures and strategies are reported to the Board of Directors through the Sustainability Committee, and important strategies are decided at Board of Directors meetings.

Through this kind of management, we believe it is possible to remain a company that meets the demands of society through sustainable business development.

Addressing the Rising Costs Associated with Climate Change Strategies

As an initiative to reduce environmental impact, SEKISUI CHEMICAL Group is working to promote visualization of energy use while reducing the amount by transforming and improving production processes, and continuously upgrading equipment for the purpose of greatly increasing energy efficiency in production processes.

SEKISUI CHEMICAL Group has been switching to purchased power generated from renewable energy sources since fiscal 2020. In Japan, we are promoting the use at our factories of SMARTHEIM DENKI, a power trading service that purchases surplus electricity from solar power generation equipment installed on the roofs of customers’ detached houses sold by the Company.

Product Development and Strategies Aimed at Solving Environmental Issues and Meeting the Changing Needs of the Market

SEKISUI CHEMICAL Group manages risks that arise from changing market needs due to climate change and other global social issues by continuing to develop products that make a significant contribution to solving issues in the natural and social environment, and disclosing and distributing detailed data on outcomes. At the same time, we believe that it will surely seize the opportunity of “increasing demand”.

In particular, we believe it is possible to magnify the impact we create by quantifying as much as possible the size of the contribution Group products make to solving social issues, which leads to opportunities to create markets in ways that help solve global issues and heighten the awareness of consumers.

From fiscal 2020, we intend to strengthen our partnerships with stakeholders and engage in activities to increase our contribution to solving issues through co-innovation (fusion) and accelerate solutions through early dissemination. With this in mind, we established the MINASE INNOVATION CENTER (MIC) as an organization to promote open innovation with our stakeholders.

MIC has started to accelerate efforts to solve social issues by actively engaging in technological exchanges with startup companies that possess low-carbon technologies, and materials and technologies that contribute to resource conversion.

Addressing the Deterioration in Operating and Working Conditions

If climate change becomes a grave problem and the highest and lowest temperatures become increasingly extreme, it is possible that people in manufacturing and construction will no longer be able to work. SEKISUI CHEMICAL Group believes that it is possible to minimize the effects of climate change by proposing construction and engineering plans that take into account the seasonality of each region.

Each divisional company and Group subsidiary has formulated its own BCP based on its unique situation as a means of avoiding as much as possible the risk of loss in operations and work availability due to natural disasters.

Acquisition of Certification under the SBT* Initiative for Greenhouse Gas Reduction Targets

SEKISUI CHEMICAL Group discloses its targets on its website and elsewhere in order to demonstrate to society its commitment as a company to proactively addressing climate change issues. Additionally, in fiscal 2017, the Group applied for certification under the SBT Initiative to demonstrate that the medium- to long-term targets announced for its overall businesses and for its supply chains reach a scientifically grounded, ambitious level aimed at achieving the COP21 (Paris Agreement) targets. The Group then became the first in the chemical sector worldwide to receive this certification.

<Certified Targets>

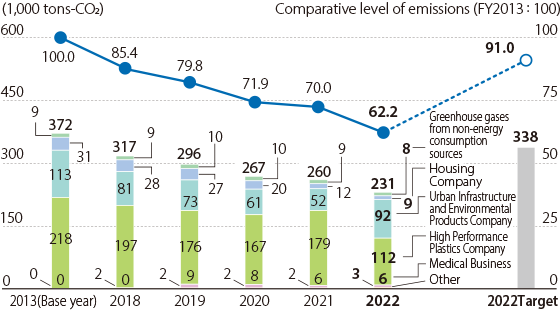

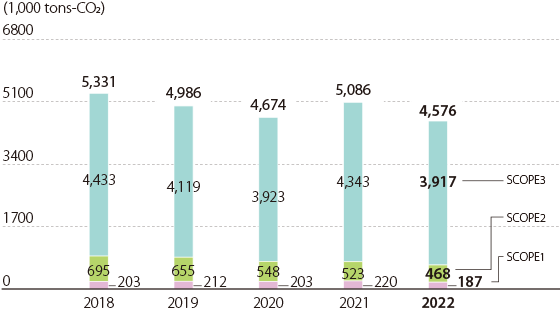

SCOPE 1+2: Reduce greenhouse gas emissions by 26%, relative to fiscal 2013, by 2030

SCOPE 3: Reduce greenhouse gas emissions by 27%, relative to fiscal 2016, by 2030

<Progress in Fiscal 2021>

SCOPE 1+2: Reduced greenhouse gas emissions by 16.9%, compared to fiscal 2013*

SCOPE 3: Reduced greenhouse gas emissions by 1.3%, relative to fiscal 2016

- Data revised for improved accuracy.

The Group will continue to affirm its growing responsibility to play its role as an industry leader and will strive to engage in activities leading and imploring society as a whole to work on measures to address climate change.

-

* SBT:SBT (Science-Based Targets). Called for by joint initiatives, including the UN Global Compact, in response to the adoption of the Paris Agreement. Through the SBT Initiative, greenhouse gas reduction targets established by companies are certified as targets that are scientifically based (SBT) that contribute to long-term measures combating climate change.

Promoting the Use of Renewable Energy in Electricity by Joining RE100

We recognize that the issue of climate change is not only a major social challenge, but also a major risk factor for SEKISUI CHEMICAL Group.In August 2020, we joined the international initiative RE100, which aims to procure the energy consumed in business activities entirely from renewable energy, in order to accelerate efforts that contribute to solving this problem in society as a whole. In the future, we will promote activities in cooperation with member companies and organizations.

To achieve zero GHG emissions from our business activities by 2050, and to attain the greenhouse gas reduction target certified by the SBT Initiative by fiscal 2030, SEKISUI CHEMICAL Group will enact strategies such as entrenching energy conservation measures and promoting a shift to renewable energy.

We intend to shift to renewable energy sources for 100% of the electric power we purchase from external sources by 2030, and aim for all our electric power, including that produced by cogeneration systems, to come from renewable energy sources by 2050.

Reducing Greenhouse Gases at the Supply Chain Stage

In the case of SEKISUI CHEMICAL Group, we were able to determine that greenhouse gas emissions falling under SCOPE 3 are highest at the raw materials procurement and product use stages. The reason that emissions are high in the raw materials procurement stage is because of the characteristics of our business as a chemicals manufacturer.

Meanwhile, emissions from the product-use stage arise from the large volumes of greenhouse gases emitted as the result of the energy consumed by the houses that we sell.

Moving forward, we will review our selection criteria for new materials, with the goal of reducing greenhouse gas emissions by 20% compared to fiscal 2016 for raw materials. We have also begun working with suppliers to reduce the use of four resins known to be raw materials that result in high levels of emissions.

In terms of emissions at the stage of product use, we will contribute to energy use reductions from occupied housing by increasing the proportion of net-zero energy houses (ZEH) among the housing units that we sell, achieving 50% reductions, relative to fiscal 2016, by fiscal 2030.

Promoting the Use of Renewable Energy

SEKISUI CHEMICAL Group has been promoting the use of renewable energy by installing solar power generators at its domestic and overseas production sites.

The following manufacturing sites have installed solar power generation equipment producing electricity for in-house use in fiscal 2021.

- Sekisui Medical Technology (China) Ltd.

- Sekisui Chemical Co., Ltd. Taga Plant

- Sekisui Medical Co., Ltd. Tsukuba Plant (Phase 3)

- 08-75

- 08-77

- 08-76

-

Sekisui Medical Technology (China) Ltd.

-

Sekisui Chemical Co., Ltd. Taga Plant

-

Sekisui Medical Co., Ltd. Tsukuba Plant (Phase 3)

| Solar Power Generation Facilities Producing Electricity for On-site Use | |

|---|---|

| Japan | Tohoku Sekisui Heim Industry Co., Ltd. |

| Chushikoku Sekisui Heim Industry Co., Ltd. | |

| Kyushu Sekisui Heim Industry Co., Ltd. | |

| Sekisui Heim Industry Co., Ltd. Kanto Site | |

| Yamanashi Sekisui Co., Ltd. | |

| SEKISUI SEIKEI, LTD. Kanto Plant | |

| Sekisui Medical Co., Ltd. Tsukuba Plant | |

| Sekisui Chemical Co., Ltd. Taga Plant | |

| USA | SEKISUI S-LEC AMERICA, LLC. |

| Netherlands | SEKISUI S-LEC B.V. Film Plant |

| Thailand | SEKISUI S-LEC (THAILAND) CO., LTD. |

| China | Sekisui Medical Technology (China) Ltd. |

SEKISUI CHEMICAL Group has also begun proactively switching over to renewable energy sources for electricity purchased from fiscal 2020, and there are currently a total of 20 facilities in Japan and overseas where 100% of electric power is derived from renewable energy.

| Facilities for which 100% of electricity is derived from renewable energy sources | |

|---|---|

| Japan | Hokkaido Sekisui Heim Industry Co., Ltd. |

| Tohoku Sekisui Heim Industry Co., Ltd. | |

| Sekisui Heim Industry Co., Ltd. Kanto Site | |

| Sekisui Heim Industry Co., Ltd. Chubu Site | |

| Sekisui Heim Industry Co., Ltd. Kinki Site | |

| Chushikoku Sekisui Heim Industry Co., Ltd. | |

| Kyushu Sekisui Heim Industry Co., Ltd. | |

| Sekisui Board Co., Ltd. Minakuchi Plant | |

| Sekisui Board Co., Ltd. Gunma Plant | |

| Sekisui Medical Co., Ltd. Tsukuba Plant | |

| Sekisui Medical Co., Ltd. Ami Site | |

| Sekisui Medical Co., Ltd. Drug Development Solutions Center | |

| SEKISUI CHEMICAL Co., Ltd. Gunma Plant | |

| SEKISUI CHEMICAL Co., Ltd. Tsukuba Site | |

| SEKISUI CHEMICAL Co., Ltd. Tokyo headquarters | |

| Netherlands | SEKISUI S-LEC B.V. Film Plant |

| SEKISUI S-LEC B.V. Resin Plant | |

| SEKISUI ALVEO B.V. | |

| SEKISUI POLYMATECH EUROPE B.V. | |

| Spain | SEKISUI SPECIALTY CHEMICALS EUROPE S.L. |

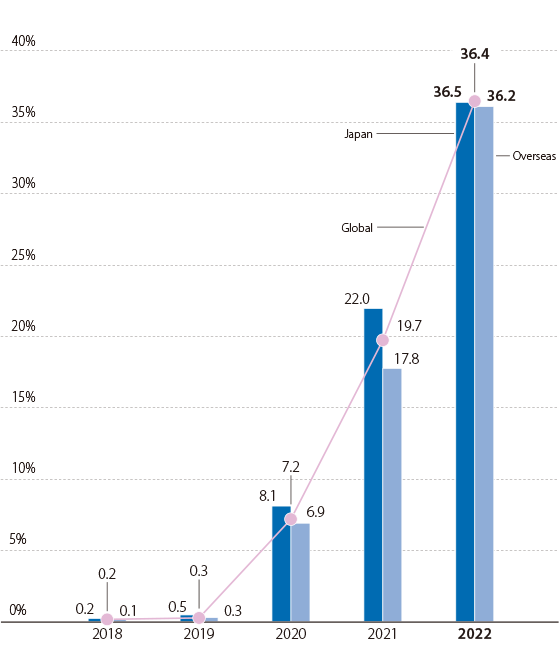

Energy consumption from renewable sources in fiscal 2021 was 144.4 GWh, comprising 17.2% of total purchased power (including solar power generation for in-house use) and 19.7% of total power consumption, including self-generated power from co-generation systems.

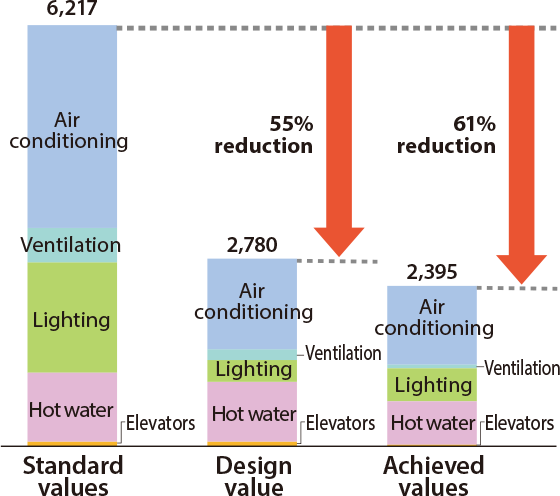

ZEB Ready* Certified New Research Facility, MINASE INNOVATION CENTER

The MINASE INNOVATION CENTER (MIC), a new research facility, was opened in Shimamoto-cho, Osaka Prefecture in August 2020. The facility was designed with a skip-floor configuration and a central atrium so as to make the entire building a space for people to interact. While this gives the building a complex shape, it has also been certified as ZEB Ready thanks to the adoption of fixtures and equipment that contribute to energy conservation, as well as a design that makes the best use of solar energy.

We have been able to engage in continuous operations at a total volume that meets design values for the past two years. Meanwhile, energy use in air conditioners and lighting exceeded design values. We believe that the increase in human resources and subsequent increase in activity is the main reason behind this compared with when the facility first opened. In fiscal 2022, we will promote activities that will help achieve energy saving performance by further upgrading and expanding rules.

- ZEB (Net Zero Energy Building): Buildings that reduce annual primary energy consumption balance to zero.

ZEB Ready: Advanced buildings in anticipation of ZEB certification, buildings with high thermal insulation and highly efficient energy-saving equipment.

(From the Ministry of the Environment web page [Japanese language only]: http://www.env.go.jp/earth/zeb/terms/index.html?id=term_01)

- 11-38

- 11-37

- 11-122

-

Primary energy consumption (fiscal 2021)(GJ/m2 per year)

-

MINASE INNOVATION CENTER (exterior view)

-

MINASE INNOVATION CENTER (interior view)

Contribute to Carbon Reduction and Decarbonization through Our Businesses

SEKISUI CHEMICAL Group is promoting the creation and expansion of markets through its in-house Products to Enhance Sustainability system. This initiative is designed to help accelerate the Group’s contribution through its businesses and the realization of a decarbonized society in 2050.

Products that not only help mitigate the effects of climate change, but also adapt to changes in the environment are considered important from a roadmap perspective. As such, we are looking to expand our lineup of these products.

Specific examples are listed as follows.

[Examples of Products That Contribute to Climate Change Mitigation]

-

<Housing>Products and services that support energy-efficient lifestyles through the use of renewable electricity

-

Example)ZEH-specification housing (net-zero energy house)

SEKISUI’s SMARTHEIM DENKI power trading service selliing surplus generated renewable energy purchased from customers of sold housing to factories and other customers

-

-

<Mobility>Lightweight and highly functional products that reduce energy consumption during transportation and shipping

-

Example)S-LEC® interlayer film for automotive laminated glass that boasts thermal and acoustic

insulation functions

Sheet materials used in aircrafts, trains, etc. (SEKISUI KYDEX product)

-

-

<Electronics>Materials indispensable for energy-efficient products, products that contribute to improving the durability and performance of related parts, which are becoming increasingly important with the development of 5G connectivity, etc.

-

Example)Heat release materials that help mitigate issues caused by overheating circuit boards (Sekisui Polymatech Co., Ltd. product)

Materials used in energy-efficient equipment (Micropearl), functional tape

-

[Examples of Products That Adapt to Changes in the Climate]

-

<Building & Civil Engineering>Products that help manage natural disasters that are increasing or becoming more severe due to the progression of climate change

-

Example)Products that enable the temporary storage of rainwater during periods of torrential rain

-

[Initiatives Undertaken in Collaboration with Other Companies]

Carbon recycling technology project partnership with ArcelorMittal, S.A.

SEKISUI CHEMICAL and ArcelorMittal concluded a partnership to pursue a project to capture and re-use the CO2 emitted during the steelmaking process in a bid to reduce the dependence on fossil resources and contribute to the decarbonization of steelmaking. Through this project, energies will be directed toward developing technologies that separate, recover, and reuse the CO2, which would otherwise have been emitted into the atmosphere during the steelmaking process. Key to this work is SEKISUI CHEMICAL’s innovative technology that converts CO2 to carbon monoxide at high yields.

[Progress against Commitments]

Expanding the market penetration rate of ZEH- specification housing

In order to reduce the consumption of energy derived from fossil resources by customers living in Sekisui Heim homes sold by the company, we are committed to and are considering various measures aimed at expanding the penetration rate of ZEH-specification housing. In fiscal 2021, the ratio of new detached net-zero energy houses (ZEH) (actual results compiled in accordance with ZEH builders’ reporting methods) was 82%, and 89% after including the Nearly ZEH and ZEH oriented categories. The number of storage cell-equipped homes (energy self-sufficient houses) proposed in conjunction with ZEH houses has also increased on a cumulative basis, and the storage cell installation rate for new detached homes has grown to 72%*.

- Contract-based storage cell installation rate from April 2021 to March 2022 (Company data)

Activities in related initiatives

[Aimed at mitigating climate change]

The Japan Climate Initiative (JCI)

-

Significance/objectives・・・The Group is joining the front line of the global push for decarbonization from Japan in order to mitigate climate change.

-

Activities・・・・・・・・・・・・・・・・In order to drive social change and help realize decarbonization, the JCI promotes information dissemination from and opinion exchanges with companies, local governments, and NGOs that are actively engaged in addressing climate change. Central to efforts aimed at accelerating activities through corporate collaboration, we are promoting the declaration of goals and activities to achieve objectives.

-

Our Company’s role・・・・・・We share the latest information on our initiatives and using them to consider measures.

RE100

-

Significance/objectives・・・Aim for companies to cover 100% of the electricity used in their operations from renewable energy sources

-

Activities・・・・・・・・・・・・・・・・Motivated companies that have made declarations cooperate with each other to communicate and are promoting communication and activities that have an impact on society.

-

Our Company’s role・・・・・・We are contributing to greater use and diffusion of renewable energy in society by declaring our commitment to shifting toward renewable energy.

JAPAN CLIMATE LEADERS’ PARTNERSHIP (JCLP)

-

Significance/objectives・・・Aim to realize a rapid transition to a decarbonized society and achieve the 1.5°C target to avert a climate crisis.

-

Activities・・・・・・・・・・・・・・・・Leading Japan in five pillars to achieve policy changes

Pursuing policy engagement, promoting decarbonization within companies, providing solutions to decarbonize society, communicating with society, and cooperating with global networks -

Our Company’s role・・・・・・Decarbonize the Company and society by making a decarbonization declaration, transitioning to a decarbonized business model, and pursuing corporate collaboration to promote internal decarbonization mainly within supply chains.

-

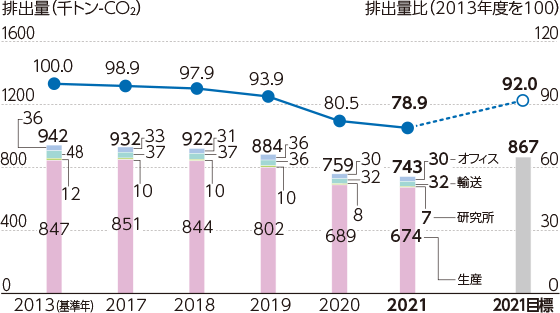

Note 1:In addition to SCOPE 1+2, SEKISUI CHEMICAL GROUP manages greenhouse gas (GHG) emissions that arise from its business activities including transportation.

-

Note 2:As of fiscal 2019, results from the medical business are collated and presented with Corporate Headquarters results following its separation from the High Performance Plastics Company.

- 11-39

-

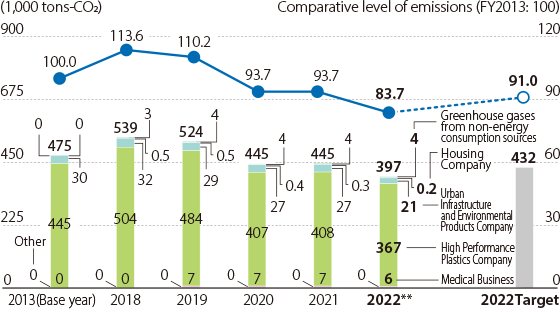

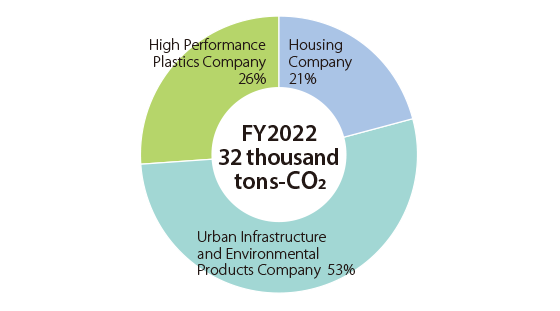

Greenhouse Gas (GHG) Emissions from Business Activities

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

- 11-40

- 11-41

-

Greenhouse Gas (GHG) Emissions during Manufacturing / Japan

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

-

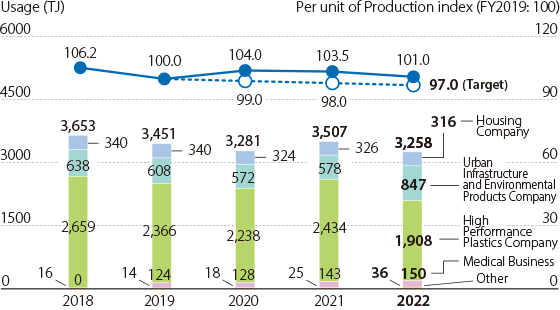

Energy Use and per Unit of Production* (Index) during Manufacturing / Japan

- Energy consumption per unit of production weight

-

Note:Data for 2019 and after have been revised to improve accuracy.

- 11-42

- 11-43

-

Greenhouse Gas (GHG) Emissions during Manufacturing / Overseas

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

-

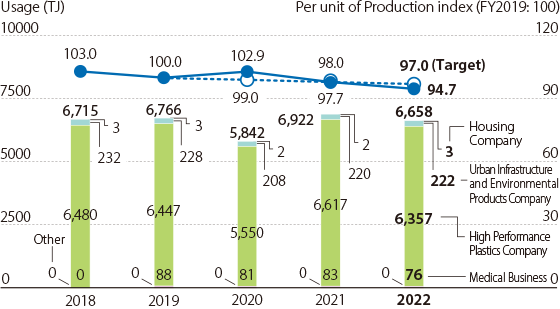

Energy Use and per Unit of Production* (Index) during Manufacturing / Overseas

- Energy consumption per unit of production weight

-

Note:Data for 2019 and after have been revised to improve accuracy.

- 11-44

- 11-45

-

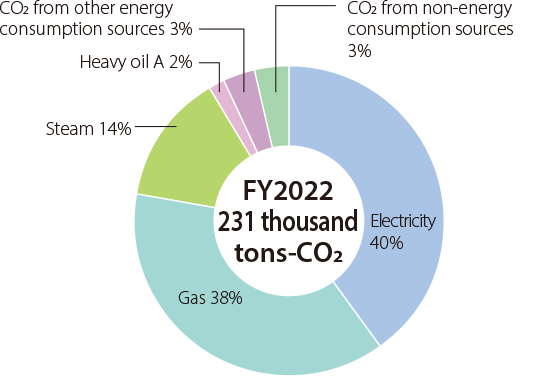

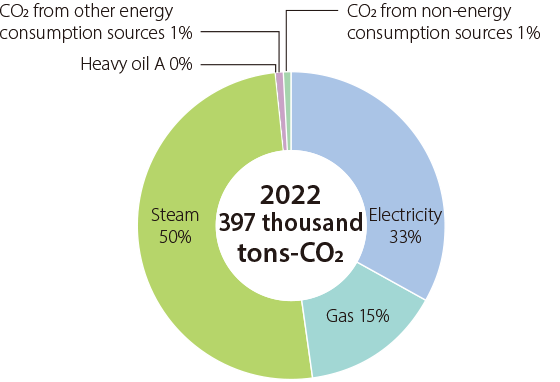

Breakdown of Greenhouse Gas (GHG) Emissions during Manufacturing / Japan

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

-

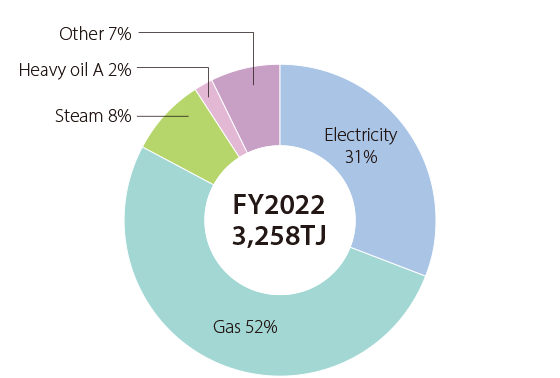

Breakdown of Energy Use during Manufacturing / Japan

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

- 11-46

- 11-47

-

Breakdown of Greenhouse Gas (GHG) Emissions during Manufacturing / Overseas

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

-

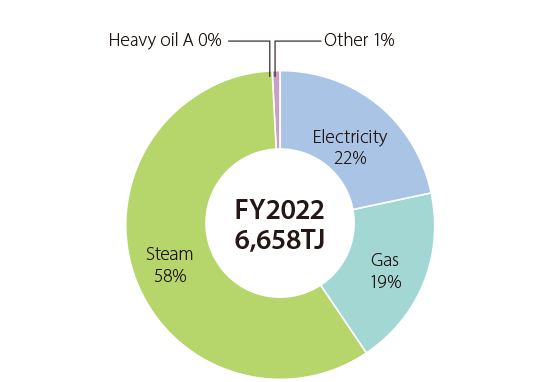

Breakdown of Energy Use during Manufacturing / Overseas

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

- 11-48

- 11-130

-

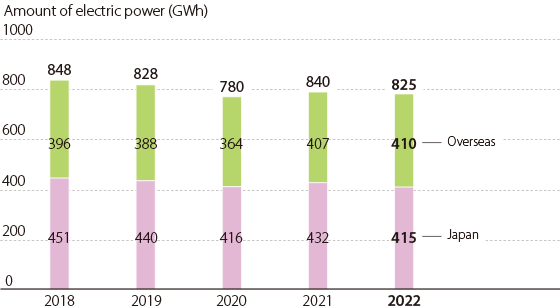

Electricity Consumption in Japan and Overseas/ Domestic Production Sites and Research Laboratories, Overseas Production Sites, Domestic and Overseas Offices

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

-

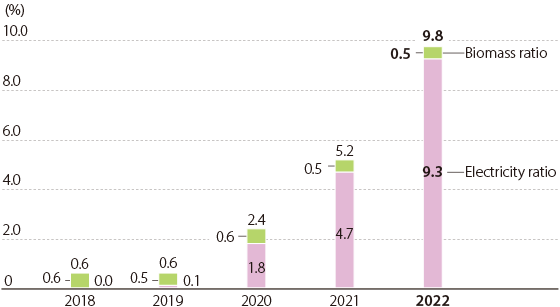

Ratio of Renewable Energy to Total Energy Consumption/ Electricity, Biomass Boilers

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

- 11-49

- 11-135

-

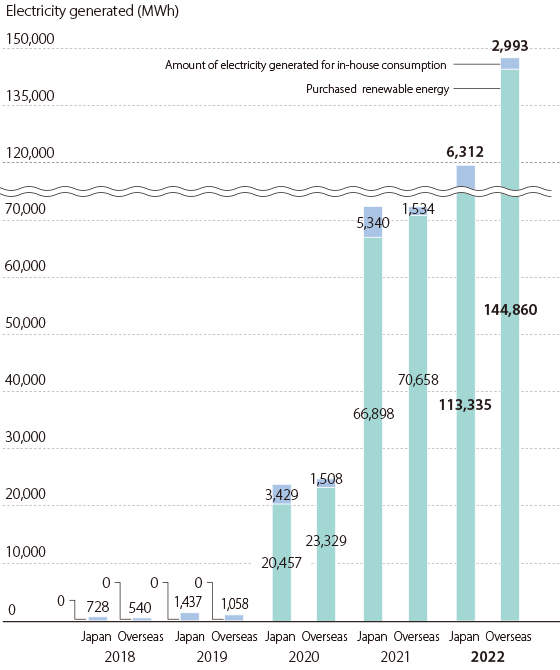

Energy generated for in-house consumption, amount of purchased electricity, and domestic and overseas

*excluding co-generation

- Past figures have been retroactively revised due to changes in aggregate scope.

-

Ratio of electricity derived from renewable energy sources/domestic and overseas

*excluding co-generation

-

Note:Data for 2019 and after have been revised to improve accuracy.

-

| Indicator | Calculation Method |

|---|---|

| Greenhouse Gas Emissions | GHG emissions = Σ[fuel use, purchased electricity, purchased steam × CO2 emissions coefficient] + greenhouse gas emissions not arising from energy consumption Greenhouse gas emissions not arising from energy consumption = CO2 emissions not arising from energy consumption* + Σ[emissions of non-CO2 greenhouse gases × global warming potential] *Includes CO2 emissions from burning of non-fuel gases based on local laws related to countermeasures on global warming, both inside Japan and overseas [CO2 Emissions Coefficient]

|

| Energy Use | Energy use = Σ[amount of fuel used, amount of electricity purchased, amount of solar power generation for in-house use, and amount of steam purchased x unit calorific value] [Unit Calorific Value]

|

- 11-55

- 11-56

-

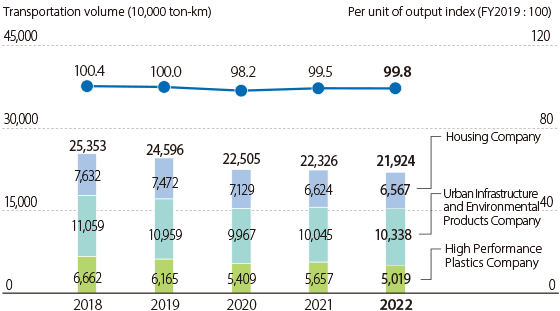

Transportation Volumes and Energy per Unit of Transportation (Index) / Japan

-

CO2 Emissions during the Transportation Stage / Japan

| Indicator | Calculation Method |

|---|---|

| CO2 Emissions during the Transportation Stage | The calculation is made by combining the fuel consumption method (transport of housing units, etc.) and the improved ton-kilometer method (other than transport of housing units, etc.) CO2 emissions = Σ[fuel use × CO2 emissions coefficient] + Σ[amount transported (metric tons) × distance transported (km) × fuel use per unit of transportation × CO2 emissions coefficient] Fuel use per unit of transportation is the value used in the reporting system for specified freight carriers under the Act on the Rational Use of Energy Domestic distribution (shipment of products) is covered |

- 11-58

-

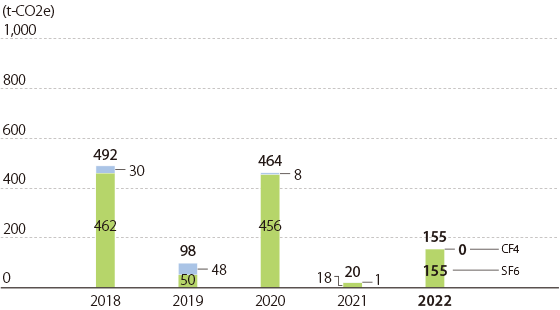

Emissions of Non-CO2 Greenhouse Gases (Global Production, Laboratories)

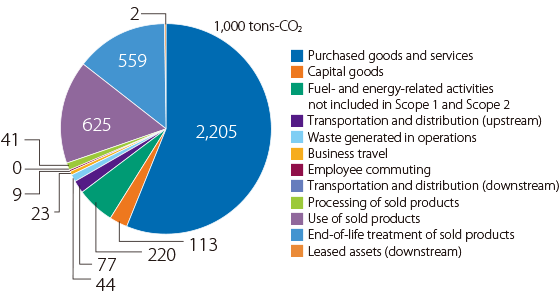

Greenhouse Gas Emissions throughout Our Supply Chain (SCOPE 3)

| Category | |||||||

|---|---|---|---|---|---|---|---|

| FY2016 | FY2017 | FY2018 | FYFY2019 | 2020 | FY2021 | ||

| Upstream | Purchased goods and services | 2,180 | 2,336 | 2,457 | 2,352 | 2,282 | 2,445 |

| Capital goods | 37 | 171 | 123 | 96 | 80 | 74 | |

| Fuel-and energy related activities not included in Scope 1 and Scope 2 | 127 | 131 | 129 | 127 | 198 | 226 | |

| Transportation and distribution (upstream) | 37 | 46 | 48 | 48 | 43 | 48 | |

| Waste generated in operations | 46 | 42 | 44 | 44 | 37 | 41 | |

| Business travel | 26 | 30 | 27 | 24 | 7 | 6 | |

| Employee commuting | 5 | 6 | 6 | 6 | 5 | 4 | |

| Downstream | Transportation and distribution (downstream) | 45 | 45 | 50 | 48 | 43 | 45 |

| Processing of sold products | 43 | 46 | 48 | 45 | 39 | 41 | |

| Use of sold products | 1,542 | 1,554 | 940 | 772 | 708 | 810 | |

| End-of-life treatment of sold products | 310 | 529 | 560 | 558 | 481 | 601 | |

| Leased assets(downstream) | 1 | 1 | 1 | 2 | 1 | 1 | |

| Total(upstream/downstream) | 4,400 | 4,937 | 4,433 | 4,119 | 3,923 | 4,343 | |

-

Note:From fiscal 2018, emissions related to "use of sold products" have decreased by including the effect of reducing energy consumption in ZEH-specification houses.

- 11-60

- 11-61

Greenhouse Gas Emissions throughout Our Supply Chain as a Whole (Classified by SCOPE)

-

Note:From fiscal 2018, emissions related to "use of sold products" have decreased by including the effect of reducing energy consumption in ZEH-specification houses.

-

Note:Data for 2019 and after have been revised to improve accuracy.

| Indicator | Calculation Method | |

|---|---|---|

| Greenhouse Gas Emissions throughout Our Supply Chain | Purchased Goods and Services | CO2 emissions = ∑[(amount of major raw materials used (excluding substances subject to regulation by the PRTR Law) as listed in Material Balance section of this report + estimated values for other raw materials) × emission coefficient (Inventory Database for Environmental Analysis (IDEA) Ver.3.1 (the world’s largest GHG emissions database developed by the National Institute of Advanced Industrial Science and Technology (IDEA v.3.1))] Up to and including fiscal 2017, the Group gained an understanding of environmental impact, including the volume of greenhouse gases emitted, by making calculations using MiLCA, the database furnished by the Japan Environmental Management Association for Industry. However, from fiscal 2018, the Group is reflecting the actual emissions of its raw material suppliers with regard to four principal resins (PP, PE, PVC and PVA). |

| Capital Goods | CO2 emissions = ∑[(amount of spending on capital expenditures authorized for the given fiscal year for buildings, structures, mechanical equipment, and transport vehicles) × emissions coefficient (per unit emissions database for calculating organizational greenhouse gas emissions, etc., arising from supply chains (Ver. 3.0) (Ministry of the Environment and Ministry of the Economy, Trade and Industry))] | |

| Fuel- and Energy-related Activities not Included in SCOPE 1 and SCOPE 2 | CO2 emissions = ∑[(fuel use, amount of purchased electricity, and amount of purchased steam) × emissions coefficient] The emissions coefficients used are as follows. For fuel IDEA v.3.1 For purchased electricity and steam, per unit emission database for calculating greenhouse gas emissions by organizations, etc., arising from supply chains (Ver. 3.0) (Ministry of the Environment and Ministry of the Economy, Trade and Industry). Applicable to production sites, laboratories, and offices both inside Japan and overseas. |

|

| Transportation and Distribution (Upstream) | CO2 emissions = ∑[amount of major raw materials used (excluding substances subject to regulation by the PRTR Law) as listed in the Material Balance section of this report × transport distance × emission coefficient (IDEA v.3.1)] (Calculated assuming that the transport distance was uniformly 200 km) |

|

| Waste Generated in Operations | CO2 emissions = ∑[amount of waste materials generated (by type) × emission coefficient (IDEA v.3.1)] Scope: Major production sites and research facilities in Japan and overseas. |

|

| Business Travel | CO2 emissions = Σ[transportation costs by method of transport × emissions coefficient (per unit emissions database for calculating organizational greenhouse gas emissions, etc., arising from supply chains (Ver. 3.0) (Ministry of the Environment and Ministry of the Economy, Trade and Industry))] (Includes estimates of transportation costs for group companies) Group companies in Japan and overseas all covered. |

|

| Employee Commuting | CO2 emissions = Σ[amount spent on commuting allowance × emissions coefficient (per unit emissions database for calculating organizational greenhouse gas emissions, etc., arising from supply chains (Ver. 3.0) (Ministry of the Environment and Ministry of the Economy, Trade and Industry)] (Calculated based on the assumption that all commuting is done by passenger train) (Group company commuting costs include estimates) Group companies in Japan and overseas all covered. |

|

| Transportation and Distribution (Downstream) | The calculation is made by combining the fuel consumption method (transport of housing units, etc.) and the improved ton-kilometer method (other than transport of housing unit, etc.) CO2 emissions = Σ[fuel use × CO2 emissions coefficient] + Σ[amount transported (metric tons) × distance transported (km) × fuel use per unit of output × CO2 emissions coefficient (value used in the reporting system for specified freight carriers under the Act on the Rational Use of Energy)] (Estimates used for overseas) Covers shipments of products by Group companies in Japan and overseas. |

|

| Processing of Sold Products | CO2 emissions = Σ[production volume of relevant products × emission coefficient at the time of processing the relevant products (IDEA v.3.1)] Covers products for the automotive industry by Group companies in Japan and overseas. |

|

| Use of Sold Products | CO2 emissions = Σ[number of structures sold as housing during the relevant fiscal year × amount of electricity purchased from power companies throughout a year × 60 years × electricity-based emissions coefficient] The amount of electricity purchased from power companies throughout a year is based on the Electricity Income and Expenditure Home Survey of Houses with Built-In Solar Power Generation Systems (2018). The electricity-based emissions coefficient employed is the emissions coefficient from the fiscal 2021 report produced by the Act on Promotion of Global Warming Countermeasures reporting system (alternate value), equal to 0.470 metric tons-CO2 /MWh. The calculation is performed under the assumption that housing will be used for 60 years. Housing sold within Japan for the fiscal year relevant to the calculation is covered. Up to and including fiscal 2017, the Group calculated the amount of greenhouse gas reduction achieved through solar power generation as the amount of reduced environmental impact. From fiscal 2018, however, we are also calculating the effect of reduction in energy used in residences built to zero energy house (ZEH) specifications. |

|

| End-of-life Treatment of Sold Products | CO2 emissions = Σ[amount of major raw materials used in the products sold during the relevant fiscal year × emission coefficient (IDEA v.3.1)] The calculation assumes that products sold during a given fiscal year are disposed of during the same fiscal year. |

|

| Leased Assets (Downstream) | Calculated to cover construction related to the installation of machinery leased by SEKISUI CHEMICAL CO2 emissions = Σ[relevant installation units × fuel usage per unit x CO2 emissions coefficient (an emissions coefficient determined based on a system of greenhouse gas emission calculations, reports, and official disclosures)] |

|