Realizing Resource Recycling

Working to Reduce Waste and Increase Recycling Throughout Product Life Cycles

Promoting resource recycling in aims of achieving a circular economy

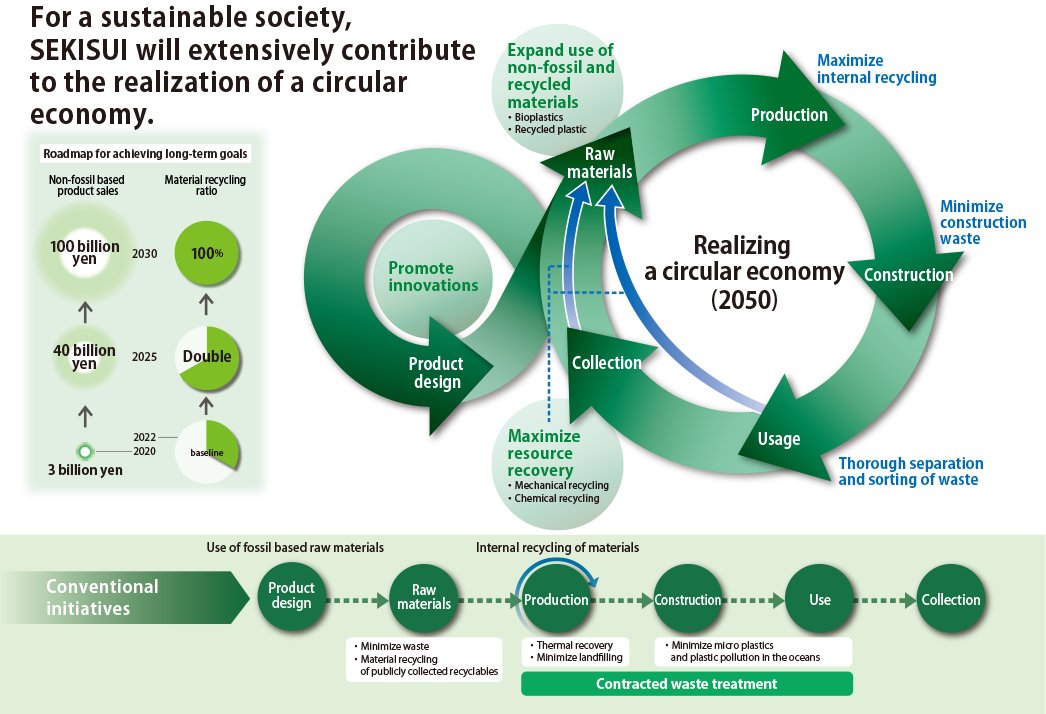

SEKISUI CHEMICAL Group aims to realize a circular economy and a sustainable society in 2050. To achieve this long-term goal, we established a resource recycling policy and strategy in fiscal 2020.

In partnership with our supply chain, we minimize the consumption of virgin raw materials derived from fossil fuels. In addition, we are promoting recycling of resources through material circulation, aiming for a circular economy throughout our businesses. In order to achieve, we are intensifying our initiatives related to the following three points as our Group policy.

[Group Policy]

-

[1]Promote innovations that contribute to resource recycling

-

[2]Expand the use of non-fossil fuel-based materials and recycled materials in our business operations

-

[3]Maximize resource recovery during the entire product life cycle

- 11-132

Promoting Efforts Based on the Resource Recycling Policy

For Vision 2030, SEKISUI CHEMICAL Group will strategically expand its businesses in four domains and double sales volume through social problem-solving, aiming to achieve a sustainable society and corporate growth. In these business areas, we believe plastics will continue to be an important material. Up until now, in the production process, we have continually made efforts year after year to reduce the amount of waste generated, using waste per unit of production as an indicator for these efforts. In addition, we have carried out for example internal recycling to reuse wood scraps and other waste materials generated and implemented processing for reuse of resources including energy when disposing of materials as waste.

In our newly-determined resource recycling policy, we will expand the ratio of plastic materials we use comprised of bioplastics and other recycled materials which are not derived from fossil fuels. Regarding our production processes, we will promote internal recycling more than ever before, intensifying initiatives to minimize the waste products emitted from our construction projects. In addition, in both the use and recovery stages, we will work on our product design and supply chain to ensure products can be disposed of with thorough sorting and separation. In this way, we will promote initiatives to maximize reuse of material resources through mechanical recycle, chemical recycle, and other recycling methods.

Within these life cycles, we believe that innovation at the product design stage is important for driving the promotion of resource circulation. By designing new products and revising the various processes for existing products, we are promoting initiatives for innovation that will accelerate resource circulation.

Road Map for Long-term Goal Achievement

| 2020~2022 | By 2025年 | By 2030年 | ||

|---|---|---|---|---|

| Business strategy | Net sales of Products to Enhance Sustainability that contribute to resource circulation | 1.1 times | 1.3 times | 2 times or more |

| Raw material resource conversion | Net sales of products not derived from fossil fuels and using recycled materials | 3 billion yen | 10 billion yen | 100 billion yen |

| Recycling waste products | Rates for recycling waste plastic into new materials | Analyze current conditions and set baselines | 2 times | 100% |

Addressing Plastic Waste Issues

In recent years, plastic waste as typified by marine plastic waste has emerged as a significant environmental issue. The Group does not engage in the manufacture and sale of primary microplastics where use presupposes dissolution. However, we do recognize that plastic processed products and plastic materials contained in products that are used or discarded after use of the sold products may deteriorate in the natural environment and become microscopic if not properly treated.

-

1.Employee education

In both the products we produce and our manufacturing processes, we must correctly recognize these issues, and develop human resources who are capable of finding a resolution. To this end, we engage in employee education while promoting environmental and social contribution activities. -

2.2Contributing to the transformation of society

To ensure the proper use of plastic, SEKISUI CHEMICAL Group recognizes the importance of building social systems while promoting a shift in the awareness of each individual employee and undertaking education and training. The Group is therefore engaged in various collaborations between industry, government, and academia.

For example, in regard to the issue of marine plastics, SEKISUI CHEMICAL Group participates in the Clean Ocean Materials Alliance (CLOMA), a collaboration initiative between companies organized by the Ministry of Economy, Trade and Industry. For a fundamental solution, we are working on the common issues necessary for the social implementation of resource recycling schemes with the aim of realizing a circular economy. -

3.Creating and expanding the use of products, technologies, and services that contribute to the realization of a recycling-based society and a circular economy

SEKISUI CHEMICAL Group has developed a technology to convert combustible waste into gas and then convert that gas to ethanol, which is the raw material for plastics, by means of a microbial catalyst. Currently, a one-tenth commercial scale (processing capacity of approximately 20 tons/day) demonstration plant has been constructed in Kuji City, Iwate Prefecture, and has been in operation since this spring, for practical application of the technology in the future. -

4.Promotion of recycling back into materials

With regard to the waste generated by its production businesses, SEKISUI CHEMICAL Group has been exchanging manifests with waste contractors, and disposal has been undertaken in a proper manner. Going forward, we will continue to endeavor to improve the rate of recycling back into materials after having undertaken proper treatment.。

Promoting Packaging Material Reductions

SEKISUI CHEMICAL Group has long been an environmentally conscious company, and we are reducing packaging materials, introducing reusable boxes*, and eliminating packaging materials wherever possible, among other initiatives.

Our proactive efforts to reduce packaging since the early 2000s have enabled us to achieve significant results. We will continue these efforts in the future, taking further steps to reduce packaging waste.

As one initiative aimed at using less product packaging, we sell foldable shipping cartons and a range of plastic containers that help facilitate the implementation of returnable box systems.

- Boxes that can be used multiple times to ship materials, parts, and products between locations.

Promoting Construction Material Recycling

The housing industry is engaged in the efficient use and recycling of construction materials throughout. As a member of this industry, SEKISUI CHEMICAL Group is reducing the amount of construction waste produced when building houses and promoting recycling.

Converting External Wall Panel Scrap into Raw Materials for Products

Sekisui Board Co., Ltd. Gunma and Minakuchi business sites, which produce Sekisui Heim external wall panels, generate scrap during their production processes. Along with making efforts to reduce the scraps produced whenever possible, these sites are moving forward with in-house material recycling for any scraps that are ultimately generated.

Specifically, the scraps generated during the production of products from the completed external walls are crushed and sorted, after which the extracted wood chips and cement are used as recycled raw materials.

Contribution to Resource Recycling through Business

Without realizing a circular economy in 2050, there can be no decarbonized society. Based on its resource recycling strategy and roadmap, SEKISUI CHEMICAL Group is shifting to the use of non-fossil fuel sourced, recyclable, and related materials with respect to its plastic materials while reviewing its product design to facilitate recycling parts in a manner that contributes to the resource recycling of existing products. In doing so, we are promoting the creation and market expansion of Products to Enhance Sustainability in a bid to accelerate our contribution through our businesses.

[Examples of Products That Contribute to Resource Recycling]

-

<Building & Civil Engineering>Products that use recycled plastic as a raw material

-

Example)Products that enable the temporary storage of rainwater during periods of torrential rain (rainwater storage material Cross-Wave)

Pipes with foamed cores made from recycled materials (3-layer pipe)

-

-

<Mobility>Buy-back system to take back edge trim from customers for reuse as raw materials (SEKISUI KYDEX product)

[Initiatives Undertaken in Collaboration with Other Companies]Initiatives for the social implementation of BR technologies

We recognize the need to collaborate with companies and organizations that are active across each of the life cycle processes in order to realize product resource recycling.

SEKISUI CHEMICAL Group has rolled out a technology that converts combustible waste into ethanol using a microbial catalyst and gas fermentation process jointly developed with U.S.-based venture company LanzaTech NZ, Inc. In order to validate the viability and commercial application of this chemical recycling technology, which is essential to resource recycling, the Company, INCJ, Ltd., and SEKISUI BIO REFINERY CO., Ltd. completed construction of a demonstration plant approximately 1/10th the size of a commercial plant in Kuji City, Iwate Prefecture in April 2022. Plans are in place for the ethanol produced at the plant to be recycled as a raw material for plastics in collaboration with SUMITOMO CHEMICAL CO., LTD. which is already underway.

Collaboration with Initiatives

CLOMA (Japan Clean Ocean Material Alliance)

-

Organizer・・・・・・・・・・・・・・・・Ministry of Economy, Trade and Industry, Ministry of the Environment, and Ministry of Agriculture, Forestry and Fisheries

-

Significance/objectives・・・To solve the issue of marine plastic waste, which is a global environmental issue

-

Activities・・・・・・・・・・・・・・・・Aiming for the more sustainable use of plastic products, and the development, introduction and popularization of innovative substitutes that will lead to a reduction of plastic waste

-

Our Company’s role・・・・・・The Company holds the chairmanship of Working Group 3 (WG3), one of five key action working groups that promote activities aimed at plastic recycling through corporate collaboration. As such, the working group has as its themes the technological establishment and social implementation of chemical recycling as well as the promotion of activities to select and clear issues in the promotion of related companies

Japan Partnership for Circular Economy (J4CE)

-

Organizer・・・・・・・・・・・・・・・・Ministry of the Environment, Ministry of Economy, Trade and Industry and Keidanren Committee

-

Significance/objectives・・・Aiming to further foster understanding and promote efforts by a wide range of parties responsible, including domestic companies, as the trend toward a circular economy accelerates on a worldwide basis.

-

Activities・・・・・・・・・・・・・・・・Introduction of case studies through case study brochures, dissemination of information for the general public, and support for inter-company collaboration

-

Our Company’s role・・・・・・To accelerate the creation of new cyclical businesses and social implementation by disseminating case studies and providing feedback on in-house technologies and measures by assessing the latest information

J-CEP (Japan Circular Economy Partnership)

-

Significance/objectives・・・Regarding everything as a resource, creating a society around things, information and feelings by relationship design.

-

Activities・・・・・・・・・・・・・・・・Engage in 1) The optimal circulation of resources in Japan, and 2) The creation of businesses that contribute to the realization of the sustainable society

-

Our Company’s role・・・・・・To contribute to the realization of a circular economy by disseminating case studies and providing technical cooperation as a member of a consortium of companies

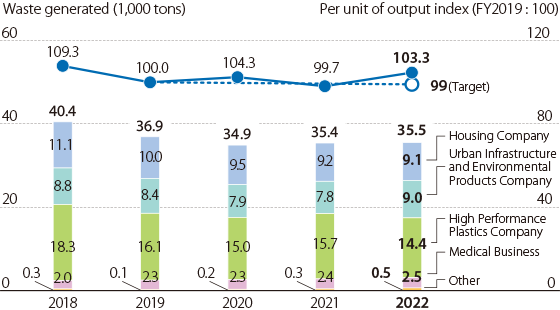

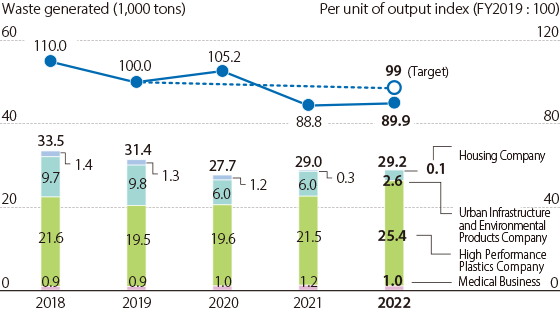

Waste Generated by Production Sites

-

Note 1:Some past figures have been revised due to improvements in calculation precision.

-

Note 2:From fiscal 2019, results from the medical business are collated and presented with Corporate Headquarters results following its separation from the HPP Company.

- 11-65

- 11-66

-

Waste Generated by Production Sites and per Unit of Production (Index) / Japan

-

Waste Generated by Production Sites and per Unit of Production (Index) / Overseas

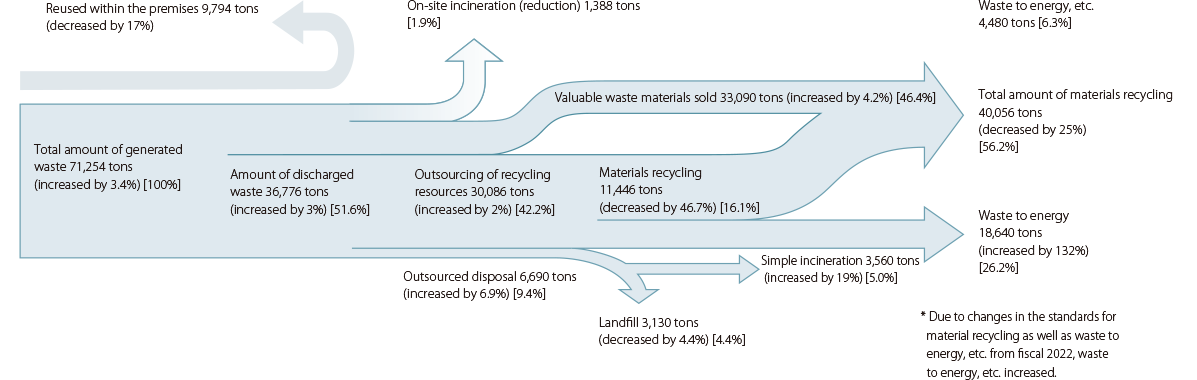

Production Site Waste Generation and Disposal / Japan and Overseas

| Total Waste | Recycled Waste | Unrecycled Waste | |

|---|---|---|---|

| FY2017 | 68,777 | 63,654 | 5,123 |

| FY2018 | 72,631 | 67,332 | 5,298 |

| FY2019 | 69,767 | 63,844 | 5,922 |

| FY2020 | 61,392 | 55,043 | 6,348 |

| FY2021 | 64,293 | 58,067 | 6,225 |

- 11-68

Fiscal 2021 Annual Production Site Waste Generation and Disposal / Japan and Overseas

Note: Change over previous year is in ( ) and proportion of total waste generation is in [ ].

- 11-69

- 11-70

-

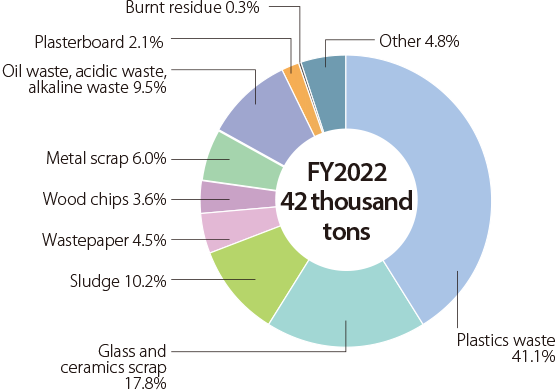

Breakdown of Waste Generated at

Production Sites / Japan

-

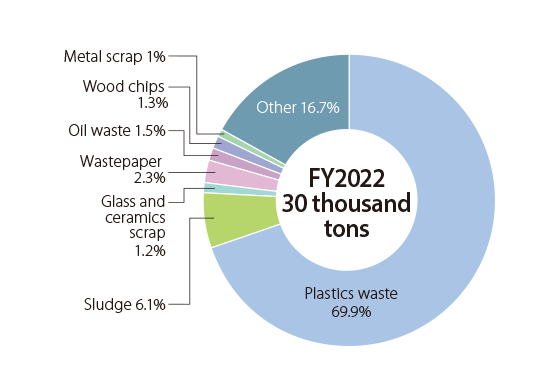

Breakdown of Waste Generated at

Production Sites / Overseas

| Indicator | Calculation Method |

|---|---|

| Generated Waste Amount | Amount of waste generated = Amount of waste collection outsourced + Amount recycled (incinerated waste to energy + recycled back to materials + recyclable waste sold) + Amount incinerated in-house; the items below are excluded: Waste generated by demolition of customers’ old houses, left-over construction materials, disposal of machinery, office equipment, etc., medical waste from medical treatment in in-house clinics |

- 11-133

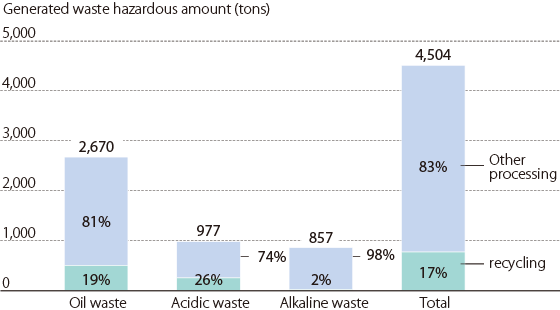

Amount of Hazardous Waste Generated/ Recycling rate (Japan and Overseas) Fiscal 2021

| Index | Calculation Method |

|---|---|

| Amount of Hazardous Waste Generated and Recycling Rate | Recycling rate = Recycled waste / Amount of hazardous waste generated Hazardous substance: Oil waste, acidic waste, alkaline waste Recycling: Material recycling |

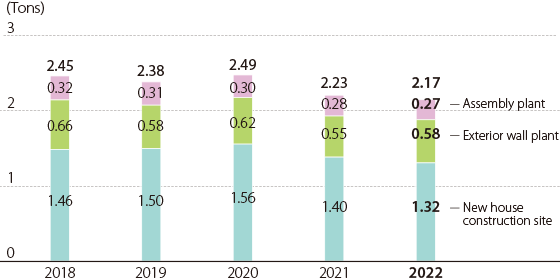

Waste Generated on Construction Sites of New Housing

- 11-72

Amount of Waste Generated on Construction Sites of New Housing (per Building) / Japan

| Indicator | Calculation Method |

|---|---|

| Amount of Waste Generated on Construction Sites of New Housing | Amount of waste generated on construction sites of new housing = Amount of waste generated during construction of outer walls (at factory) + Amount of waste generated during assembly (at factory) + Amount of waste generated at construction site of new housing Amount of waste generated per building during construction of new housing = Total amount of waste generated during construction of new houses / Number of new houses sold Scope: Housing business in Japan |

Waste Generated in Offices

- 11-74

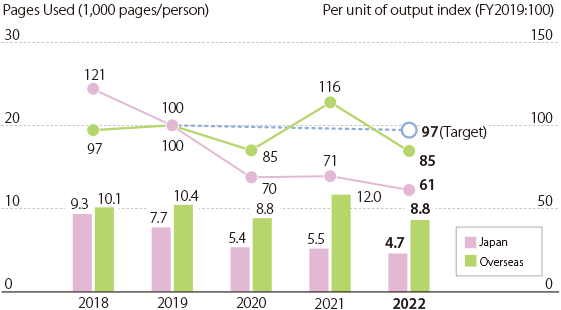

Amount of Copy Paper Used at Offices per Person (Index)