New Business

Corporate R&D is developing businesses that will become the future core business (next frontiers) for SEKISUI CHEMICAL Group.

We are focusing on creating innovations that can contribute to solving social issues, primarily in areas such as the environment and energy.

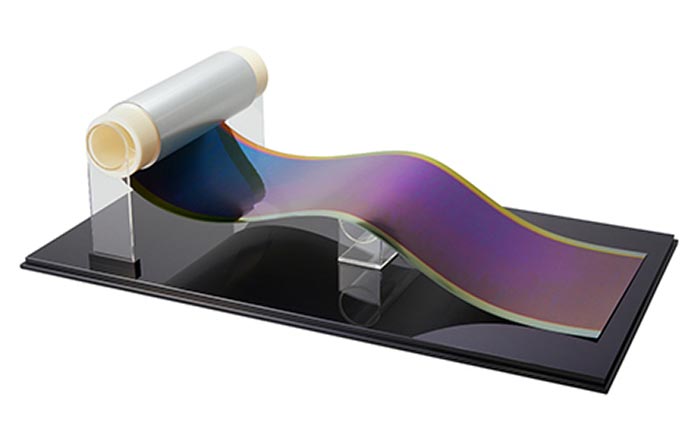

Perovskite Solar Cells

We are working on the development of perovskite solar cells to contribute to Japan’s decarbonization.

Taking advantage of their lightweight and flexibility, we aim to establish installation methods for them on building walls where conventional silicon solar cells cannot be installed, as well as gymnasiums and plant roofs that have load restrictions.

We are actively working on verification with a view to commercialization in 2025.

- Film-type Perovskite Solar Cells Installed in Umekita (Osaka) Station

- Commencement of Joint Research on Film-type Perovskite Solar Cells with the Tokyo Metropolitan Government

- Commencement of Japan’s First Demonstration Test of Perovskite Solar Cells Installed on Exterior Walls of Buildings

- Commencement of Joint Demonstration Test of Perovskite Solar Cells with JERA

- Sponsorship of the 2025 World Exposition and Installation of Film-type Perovskite Solar Cells

- Japan’s First Mounting of Perovskite Solar Cells on Exterior Walls of Building - Renovation of Osaka Head Office -

- Plan for the World's First Mega Solar Power Generation in a High-Rise Building Using Film-type Perovskite Solar Cells

- Memorandum of Understanding Signed with the Slovak Republic for Joint Study of Perovskite Solar Cells

- Commencement of Demonstration Test for Installation of Film-type Perovskite Solar Cells on Warehouse Walls

- Commencement of Joint Demonstration Test of Floating-type Perovskite Solar Cells

- Japan's Largest-scale Verification of Film-type Perovskite Solar Cells at a Port Facility with the Tokyo Metropolitan Government

- Commencement of Joint Demonstration Test for Installation of Film-type Perovskite Solar Cells on Service Station Roofs and Tank Walls

- Commencement of First Joint Demonstration Test in Japan for Agrivoltaic Perovskite Solar Cells

- Demonstration Testing of Soundproof Walls with Perovskite Solar Cells

Stationary Lithium-Ion Batteries

We developed and commercialized revolutionary large, thin lithium-ion batteries that achieve large capacity, long life, high safety, and small footprints. Products manufactured at our domestic plants are increasingly used in homes, and save money when paired with solar power. We provide peace of mind for our customers’ lifestyles in the event of a disaster. In future, we shall move ahead with expansion to public facilities and so on, contributing to improved renewable energy rates and the creation of resilient communities.

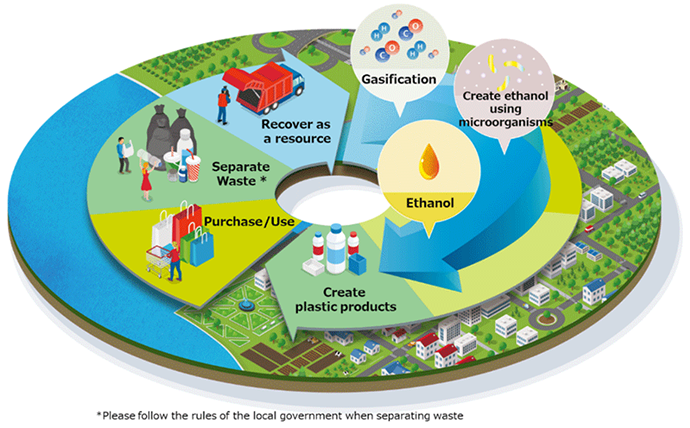

Bio-refinery

We developed technology that uses microorganisms to convert gas generated by waste incinerators into ethanol. Moving ahead with our collaborations with government and other companies, we started verification test at our demonstration plant in Kuji, Iwate Prefecture in FY 2022. The first commercial-scale BR plant is targeted to begin production in FY2028. Please also take a look at our UNISON brand, which shares a world-view of a recycling society that does not depend on fossil fuels.

Ambient-Pressure Plasma Therapy Device

Japan’s first plasma therapy device for animals, “Pidi,” is effective at reducing gum inflammation and bad breath in dogs. The active species using nitrogen gas allows treatment that is gentle and with less irritation on animals. The plasma technology we have cultivated over 20 years in semiconductors and displays has made it possible to make the device lightweight and compact.

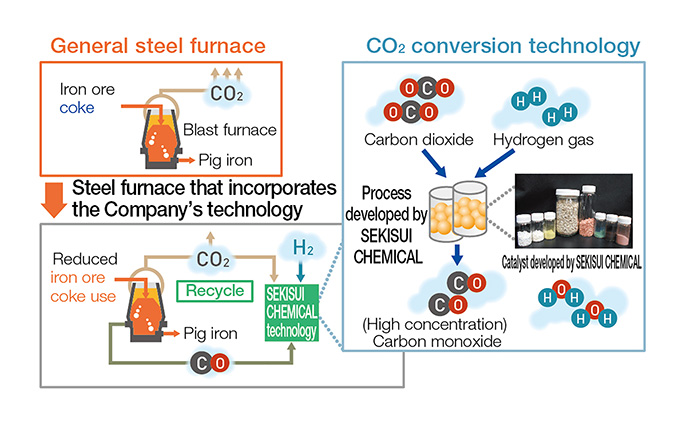

Use of CO2 in the Steel Industry

We are developing thechnology for the separation from gas, collection, and reuse of CO2 eitted when producing steel and are working on international joint research and development with ArcelorMittal, S.A., a world-leading steel and mining company, on carbon recycling for use in steel processing.

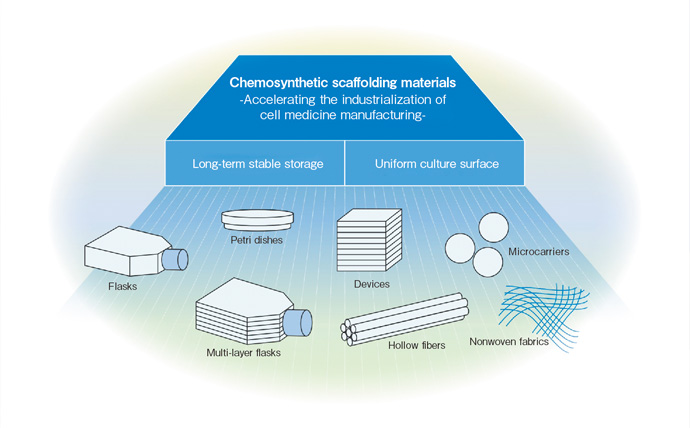

Cell Culture Scaffold Materials

iPS cells are used in cutting-edge life sciences such as regenerative medicine. We are working on developing chemically synthesized scaffolds to easily and stably cultivation of iPS cells. By applying this scaffold to the surfaces of various culture vessels, we will solve the issues faced by regenerative medicine, such as the automation of cell production and mass culturing. In collaboration with researchers and other companies, we will contribute to the creation of future medicine.