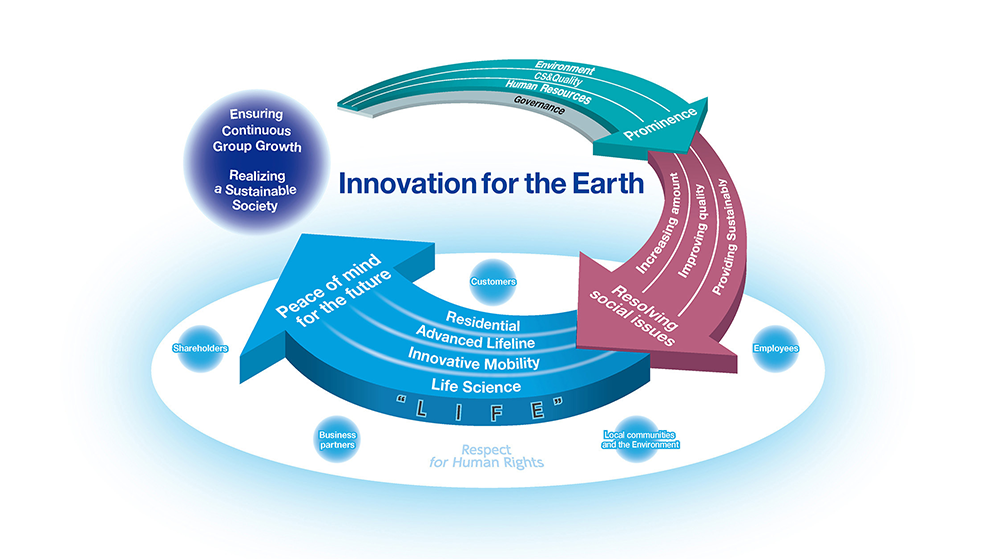

In order to realize sustainable society, we support the basis of LIFE and will continue to create peace of mind for the future.

Updated information

-

- Feb. 8, 2024

- SEKISUI CHEMICAL recognized by CDP with double ‘A’ score for transparency on climate change and water security

-

- Feb. 1, 2024

- SEKISUI CHEMICAL Group Human Rights Policy

-

- Feb. 1, 2024

- SEKISUI CHEMICAL Group Basic procurement policy

-

- Dec. 18, 2023

- SEKISUI CHEMICAL CO., LTD. has been included in the Dow Jones Sustainability Indices World Index For Twelfth Consecutive Year

-

- Oct. 24, 2023

- TCFD/TNFD Report 2023 (PDF version) has been released.

Materiality Topics

Download PDF

SEKISUI CHEMICAL Group's sustainability data is available in PDF format.