SEKISUI CHEMICAL CO., LTD., (President: Keita Kato) announces that its High Performance Plastics Company (President: Ikusuke Shimizu) has improved the performance of Photolec B, the UV + moisture curing adhesive used in gluing together electronic equipment parts. Although the product is already being used at certain smartphone manufacturers, SEKISUI CHEMICAL plans to beef up its solution proposal activities aimed at smartphone manufacturers, in order to win 15% share of the smartphone parts adhesive market by FY2022. The company plans to speed up marketing for application in other devices, chiefly in overseas markets.

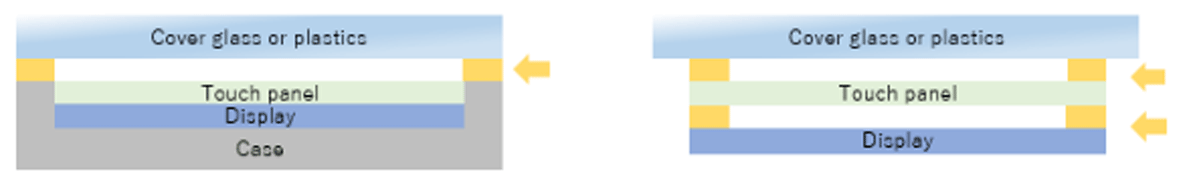

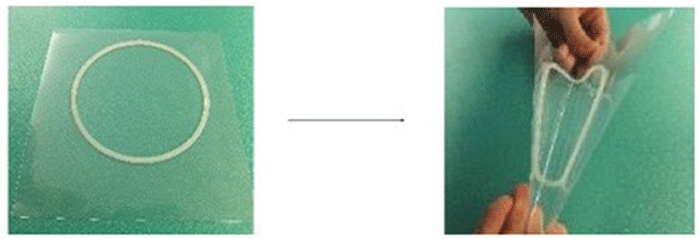

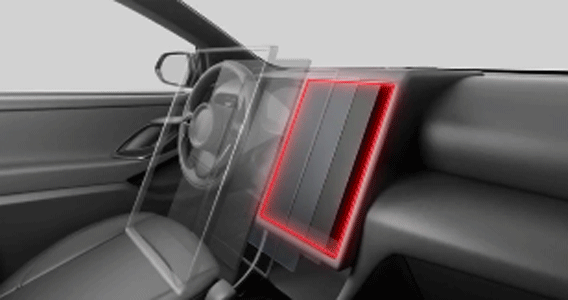

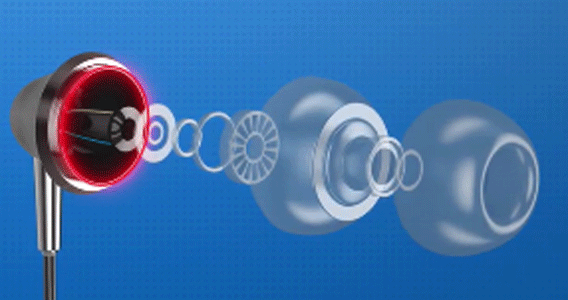

Photolec B is an adhesive used in bonding the exterior parts (case and cover glass) of the smartphone, as well as in bonding the touch panel with the cover glass and the display casing trim (see Figure 1). Because UV curing and moisture curing realize both initial adhesive strength and final adhesive strength, it is capable of dispensing glue and bonding at width of 0.4mm. It also maintains a degree of softness after curing fully and is therefore able to absorb shock when falling and helps in preventing damage of device parts. (See Figure 2) At present, this adhesion method is being employed nearly exclusively for two types of methods - double-sided adhesive tape and glues, with each holding roughly 50% in share. With promotion of Photolec B, however, marketing will be targeted to this adhesive market as well.

Figure 1 Image of Photolec B use on a smartphone

Figure 2 Photolec B keeps a degree of softness after curing

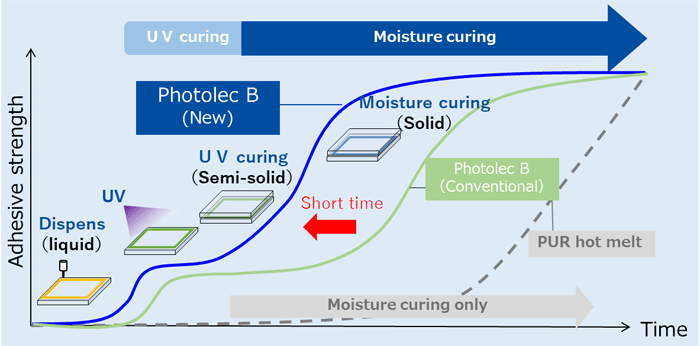

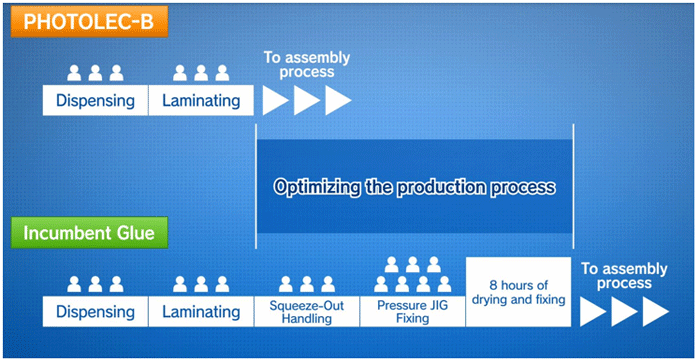

The latest upgrade was realized by change in the raw material mixing design for Photolec B, improving the initial adhesive strength after UV curing. Specifically, adhesive strength after dispensing and UV radiation is realized in a shorter period of time. (See Figure 3) This is expected to cut down the time and the use of jig tools in maintaining pressure in adhesion between parts and materials, thus contributing to manpower reduction and automation of the process. (See Figure 4)

Figure 3 Change in adhesive strength after Photolec B dispensing

Figure 4 Image of optimized production process efficiency with Photolec B

Photolec B application examples

Smartphone

Wearable device

TV, Monitor

On-Vehicle display

Small parts such as earphones

(Reference: Photolec B product website)

https://www.sekisui-fc.com/en/resin/u16.html

About SEKISUI CHEMICAL Group

Headquartered in Japan, SEKISUI CHEMICAL CO., LTD. (TSE: 4204) and its subsidiaries make up the SEKISUI CHEMICAL Group. 27,000 employees in over 200 companies throughout 21 countries aim to contribute to improving the lives of the people of the world and the earth’s environment. Thanks to a history of innovation, dedication and a pioneering spirit, SEKISUI CHEMICAL now holds leading positions in its three diverse business divisions as well as top global market share in interlayer film, foam products, conductive particles and more.

Since its foundation in 1947, the SEKISUI CHEMICAL Group has dedicated itself to social and environmental contribution and is now an internationally recognized leader in sustainability and environmental initiatives, having recently been selected as one of the Global 100 most sustainable companies. SEKISUI CHEMICAL Group will continue to maintain a strong corporate presence for 100 years and beyond.

Press Contact

SEKISUI CHEMICAL CO., LTD.

Public Relations Department

Fax: +81-(0)3-6748-6547

Disclaimer

This press release may contain forward-looking statements. Such forward-looking statements are based on current expectations and beliefs and are subject to a number of factors and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements due to changes in global economic, business, competitive market and regulatory factors.