SEKISUI CHEMICAL CO., LTD. (President: Naofumi Negishi, hereinafter called "Sekisui Chemical") has won the 6th (FY2013) Minister of Land, Infrastructure, Transport and Tourism Prize, “Junkan no Michi Wastewater System Prize.” The award giving ceremony was conducted on September 10.

1.About the Minister of Land, Infrastructure, Transport and Tourism Prize, “Junkan no Michi Wastewater System Prize”

The Minister of Land, Infrastructure, Transport and Tourism Prize established

“Iki Iki Wastewater System Prize,” in FY1992 with the aim of promoting greater

understanding and interest in the wastewater system.

Given the changes

in the situation regarding wastewater systems, and in aiming for the establishment

of a sustainable, recycling society, the Ministry of Land, Infrastructure, Transport

and Tourism released a new report titled “Wastewater System Vision 2100” in

2005. They proposed “Junkan no Michi (The Way Toward Recycling)” as a fundamental

concept behind the wastewater system of 21st century society, and established

“Mizu no Michi (The Way Toward Using Water),” “Shigen no Michi (The Way Toward

Using Resources)” and “Shisetsu Saisei no Michi (The Way Toward Restoring

Facilities)” as its three fundamental policies.

This prompted the renaming

of the prize in FY2008 to the Minister of Land, Infrastructure, Transport and

Tourism Prize, “Junkan no Michi Wastewater System Prize,” and simultaneously

resulted in the establishment of the four departments, the “Mizu no Michi Department,”

“Shigen no Michi Department,” “Sustainable Activities Department” and the

“Special Department.”

2.Details of the Prize

|

* Points to take note in the award

Sekisui Chemical has been promoting globally “SPR method,” a pipeline rehabilitation

method, developed in collaboration with Tokyo Metropolitan Sewerage Service

Corporation and Adachi Construction & Industry Co., Ltd.

Tokyo Metropolitan

Sewerage Service Corporation has been cooperating with the Tokyo Metropolitan

Government in preparing the design manual and building ties with overseas governments

to lead the way for Japanese corporations to spread the Japanese-originated

technology “SPR method.” Furthermore, Adachi Construction & Industry Co.,

Ltd. has been developing a construction machine for international use, while

Sekisui Chemical has been expanding the business overseas including the development

and manufacturing of construction materials and execution of construction work.

The

sewer line built in 1936 in Ansbach in Southern Germany had aged, requiring

urgent restoration.

This region has numerous buildings of historical

value, and it is also an area with a high concentration of residential houses,

meaning that neither traditional methods of excavation nor conventional trenchless

methods could be used, and they had been searching for a solution.

A subsidiary of Sekisui Chemical, SEKISUI SPR EUROPE, G,m.b.H. (Germany) proposed the SPR method of rehabilitating pipelines, developed in Japan, to AWEAN, a public corporation of the city, and succeeded in landing a contract in April 2013. All the work was completed at the end of July 2013.

■ The five reasons why the SPR method was implemented

|

|

(1) It is a trenchless method allowing the protection of historical buildings unlike the excavation method |

|

|

(2) Materials can be carried into the pipeline through manholes allowing minimization of the above-ground |

|

|

workspace |

|

|

(3) The method can be used on the complex, upside-down egg-shaped pipe made of bricks |

|

|

(4) The method allows work to be carried out with continued use of the pipeline in the residential area |

|

|

(5) The method minimizes the generation of waste in order to protect the historical and cultural district |

Through the rehabilitation of old pipelines using the trenchless SPR method,

we succeeded in reducing the burden on the lives of residents, the environment

and historical buildings. We restored the wastewater system, which forms a vital

part of the city infrastructure, and contributed to the stabilization of life

in the city.

There are similar situations in numerous other countries

in addition to Germany, including France, Bulgaria and Poland, and we are currently

expanding our business widely.

3.Overview of the Construction Work

|

|

Dimensions |

:Width of 1,200 mm x Height of 1,500 mm x Length of 220 m (egg-shaped pipeline) |

|

|

Existing pipeline |

:Made of bricks (constructed in 1936) |

|

|

Use |

:Wastewater system |

|

|

|

|

Residential area including historical buildings |

Existing pipeline built 77 years ago (egg-shaped pipeline made of bricks) |

|

|

|

|

|

|

|

Construction being carried out using the SPR method |

Pipeline after completion of construction |

4.About Ansbach

|

|

|

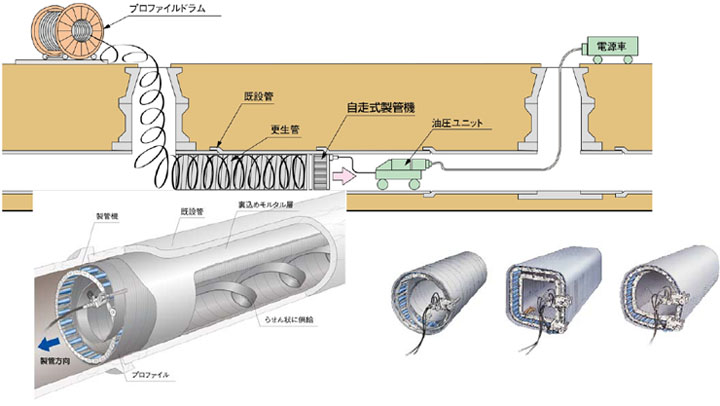

<<For reference>> About the SPR method (SPR stands for Sewage (Spirally) Pipe Renewal)

The SPR method is a way of rehabilitating (reconstructing/renewing) old pipes

by using rigid PVC made profile strip that is spirally wound into the existing

pipeline. The edges of the profile strip are interlocked to form new pipe in

the existing pipeline, and the annular gap between the spiral wound pipe and

the existing pipe is filled with a special grout. The method can be implemented

in pipelines whose diameter is from 250 mm to 6,000 mm, and it can also

be applied to non-circular and curved pipelines.

The SPR method is also

based on the world’s first, unique concept of “composite with existing pipe”

to make effective use of the structural strength remaining in the existing pipe.

It does not require to stop water flow during installation. For these reasons

it dramatically cuts construction time, costs, and the impact on residents,

society and the environment in surrounding areas, compared to methods that require

excavation of roads.

|

|

Moreover, the SPR method won the 2005 Ministry of Economy, Trade and Industry Award in the “1st Monozukuri Nippon Grand Award” and the “59th Okochi Memorial Prize, Okochi Prize” in March 2013.

|

・ |

Ministry of Economy, Trade and Industry Award in the “1st Monozukuri Nippon Grand Award” |

|

|

Name of Prize: “The Development of a Method of Completely Rehabilitating Old Wastewater Pipelines While in Continued Use.” |

|

・ |

59th Okochi Memorial Prize, Okochi Prize |

|

|

Name of Prize: “The Development and Practical Application of the Automatic Spiral Pipeline Forming and Pipeline Rehabilitation Method” |

Disclaimer

This press release may contain forward-looking statements. Such forward-looking statements are based on current expectations and beliefs and are subject to a number of factors and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements due to changes in global economic, business, competitive market and regulatory factors.