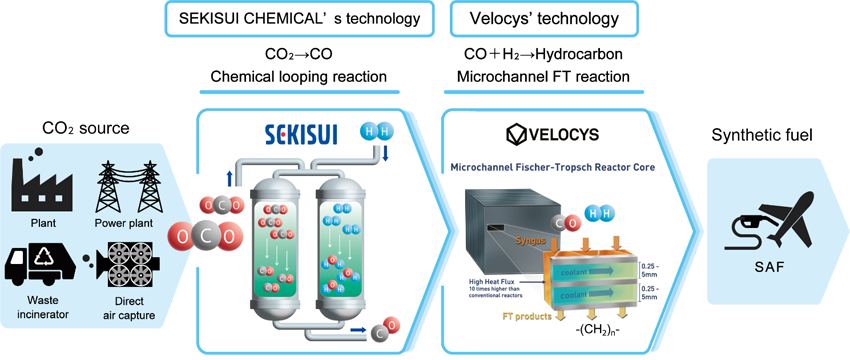

SEKISUI CHEMICAL CO., LTD. (President and Representative Director: Keita Kato; hereafter, “SEKISUI CHEMICAL”) and Velocys Inc. (CEO: Matthew Viergutz; hereafter, “Velocys”) have signed a memorandum of understanding (MoU) establishing a strategic partnership to advance production technology for electro-Sustainable Aviation Fuel (e-SAF), a CO2-derived synthetic fuel. This partnership combines SEKISUI CHEMICAL's CO2→CO chemical looping technology with Velocys' Fischer-Tropsch (FT) microchannel reactor technology to enable the manufacture of synthetic fuels using CO2 as a feedstock, thus contributing to decarbonization.

1.Background

CO2 emissions must be reduced across all industries in order to achieve carbon neutrality by 2050. The aviation industry accounts for approximately 2.6% of global CO2 emissions, and a key emission reduction measure that is gaining attention is the use of Sustainable Aviation Fuel (SAF). According to the International Energy Agency (IEA) and other organizations, 65% of CO2 reduction targets for the aviation industry can be achieved through the adoption of SAF. At present, conventional SAF is manufactured from waste oil and biomass-derived raw materials. However, considering the anticipated increase in SAF demand going forward, the early commencement and widespread adoption of e-SAF—which is manufactured from CO2 and hydrogen derived from renewable energy—is considered essential.

In this context, CO2 capture and utilization (CCU) technology, which converts CO2 into fuel and chemical products for practical use, is attracting attention. CCU technology enables the reuse of CO2 as a valuable resource and replaces fossil resources, thereby reducing CO2 emissions into the atmosphere.

2.Strengths of both companies

SEKISUI CHEMICAL is working to reduce global CO2 emissions through the social implementation of CCU technology. To date, it has developed a unique chemical looping technology that converts CO2 into CO with a high reaction yield (90% or higher).

Velocys has been developing FT reaction technology for the manufacture of synthetic fuels from synthetic gas (a mixture of CO and H2) converted from municipal waste, industrial waste, biomass, and CO2 for over 20 years. Its proprietary catalyst and microchannel reactor design have established productivity six to ten times higher than conventional FT reaction technology.

3.Collaboration overview

This project aims to establish a new e-SAF manufacturing technology by combining SEKISUI CHEMICAL’s proprietary CO2→CO chemical looping reaction technology, which achieves high reaction yields (90% or higher), with Velocys' FT reaction technology (synthetic gas → synthetic fuel), which achieves high CO conversion rates (90–95%).

In the future, the two companies will work to establish a highly efficient e-SAF manufacturing technology using CO2 as a raw material, thereby contributing to the decarbonization of the aviation industry and the realization of a sustainable society.

4.Previous initiatives of both companies

■SEKISUI CHEMICAL

SEKISUI CHEMICAL has achieved a CO reaction yield of 90% or higher using its proprietary CO2→CO chemical looping reaction technology*. It has successfully operated for a cumulative total of six months in a small-scale demonstration using exhaust gas from a steel mill (1 kg- CO2/day) and is currently conducting a survey project (NEDO “International Demonstration Project on Japan's Technologies for Decarbonization and Energy Transition (Pre-Demonstration Survey)”) aimed at a 10 t- CO2/day scale demonstration.

*This achievement is a result of NEDO’s international joint research and development project (JPNP20005) for innovative technology in the field of clean energy.

■Velocys

Velocys has conducted research and development of microchannel FT reaction technology for over 20 years. It has a proven track record of continuous operation for over 6,000 hours at a scale of up to 250 barrels per day. As part of a NEDO project to produce SAF from biomass in Japan, Velocys’ technology was used to manufacture SAF that complies with international standards and was used to fuel a commercial flight. It is currently advancing multiple low-carbon fuels projects with varying commercial production capacities.

Reference

(1) Overview of SEKISUI CHEMICAL CO., LTD.

|

Established |

1947 |

|---|---|

|

Representative |

Keita Kato, President and Representative Director |

|

Address |

2-4-4 Nishi-tenma, Kita-ku, Osaka City |

|

Employees |

26,929 |

(2) Overview of Velocys Inc.

|

Established |

2001 |

|---|---|

|

Representative |

Matthew Viergutz(CEO) |

|

Address |

15721 Park Row Blvd, Houston, TX 77084, USA |

|

URL |

About SEKISUI CHEMICAL Group

Headquartered in Japan, SEKISUI CHEMICAL CO., LTD. (TSE: 4204) and its subsidiaries make up the SEKISUI CHEMICAL Group. 26,000 employees in over 155 companies throughout 20 countries and regions aim to contribute to improving the lives of the people of the world and the earth’s environment. Thanks to a history of innovation, dedication and a pioneering spirit, SEKISUI CHEMICAL now holds leading positions in its three diverse business divisions as well as top global market share in interlayer film, foam products, conductive particles and more.

<Press contact>

SEKISUI CHEMICAL CO., LTD.

Corporate Communication Department, Public Relations Group

E-mail: kouhou@sekisui.com

<Other than the press>

SEKISUI CHEMICAL CO., LTD.

R&D Center

Advanced Technology Institute, Green Chemistry Project

E-mail: gcp_press@sekisui.com

Disclaimer

This press release may contain forward-looking statements. Such forward-looking statements are based on current expectations and beliefs and are subject to a number of factors and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements due to changes in global economic, business, competitive market and regulatory factors.