SEKISUI CHEMICAL CO., LTD. (President: Keita Kato; hereinafter “SEKISUI CHEMICAL”) is pleased to announce that its High Performance Plastics Company will release the world’s first industrial double-faced tapes, “High heat-resistant transfer tape 5503HT・5505HR,” on March 20, which feature four characteristics: high heat resistance, thin film, low VOCs, and high adhesion to rough surfaces.

*VOC (Volatile Organic Compounds)

*World's first:According to our research in 2023 Feb.

5503HT

5505HR

1. Background of the development

As environmental awareness grows worldwide, the shift from gasoline (diesel) cars to electric vehicles is further accelerating in many countries and regions. The replacement of an engine with an electric motor as the vehicle’s power source has caused problems such as securing a heat source for heating (Engine cars use engine cooling water as a heat source for heating.) and narrower spaces due to an increase in electrical components mounted on the vehicle body. The challenges are to improve “heat management efficiency associated with EVs” and to increase the “degree of freedom in vehicle interior design.”

SEKISUI CHEMICAL has been working to solve these problems for vehicle applications and has now succeeded in developing new high heat-resistant transfer tapes (base material-less tapes) that have high thermal efficiency and can directly fix protective fabrics to in-vehicle heaters.

There are four problems to be solved when fixing the protective fabric to the radiant heater installed near the passenger’s seat: (1) withstanding high temperatures, (2) being as thin as possible to reduce its thermal capacity, (3) ensuring stable adhesion to rough and uneven surfaces to cloth, and (4) being low VOC enough to be used for interior materials.

The tapes can solve the four problems with SEKISUI CHEMICAL’s proprietary adhesion and polymer polymerization technologies.

2. Product outline/Line-up

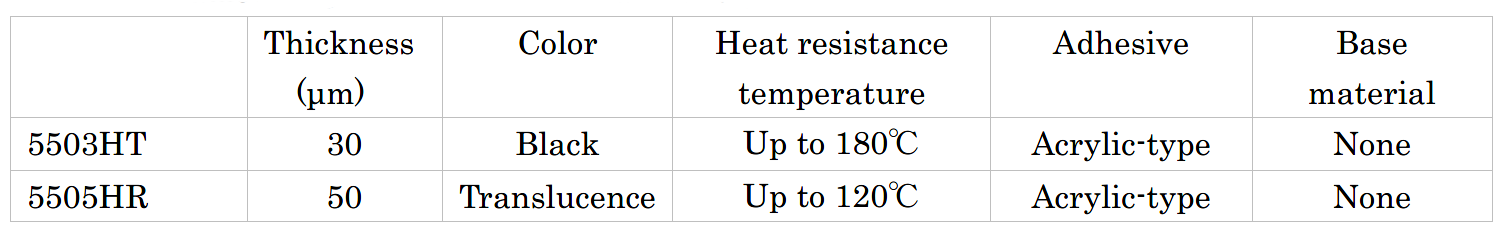

Product name: High heat-resistant transfer tape 5503HT・5505HR

*Two types are available to meet customer requirements for thickness, color, and heat resistance.

3. High Features of “Heat-resistant transfer tape 5503HT・5505HR”

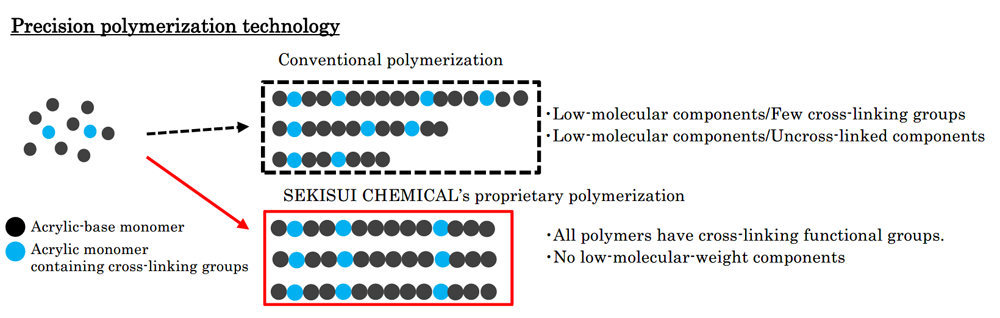

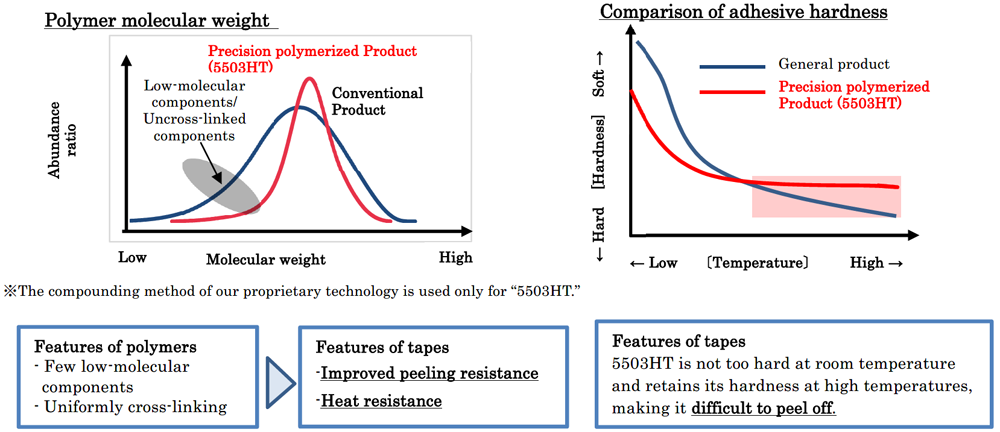

1) With the application of SEKISUI CHEMICAL’s proprietary precision polymerization technology, the tapes are thin but achieve both heat resistance and peel resistance.

The adhesive performance of tapes usually varies with their thickness. And, in general, when they are exposed to high temperatures, the adhesive usually melts and the performance deteriorates.

With the application of our proprietary adhesion technology and polymer polymerization technology, the tapes, even though they are thin-film, have both heat resistance and peel resistance.

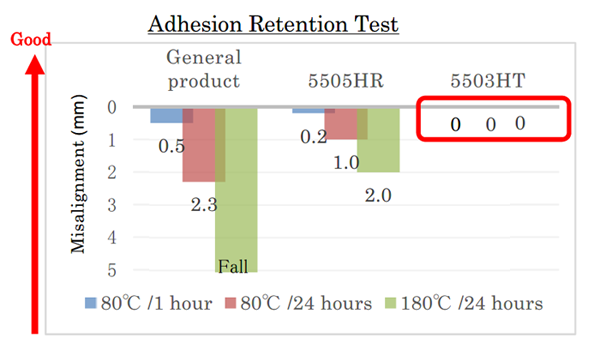

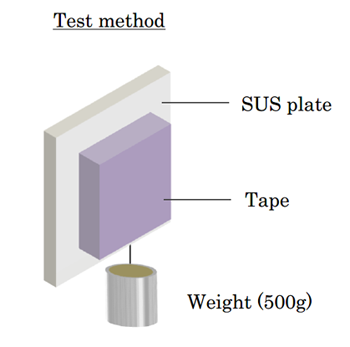

2) Heat-resistant enough not to cause misalignment even at 180℃ and strong adhesive strength even at room temperature

(1)Excellent adhesive retention at high temperatures, which could not be achieved in the past, and extremely higher heat resistance than a general tape

General tape = our acrylic double-faced tape

*The general product demonstrates sufficient adhesive performance only at temperatures below 80℃.

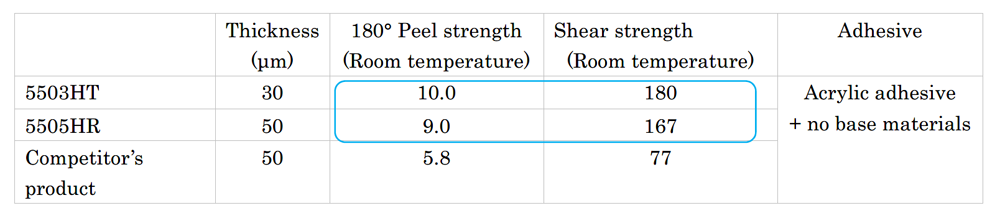

(2) Strong adhesive strength (N/25mm) even at room temperature to adhere firmly to objects

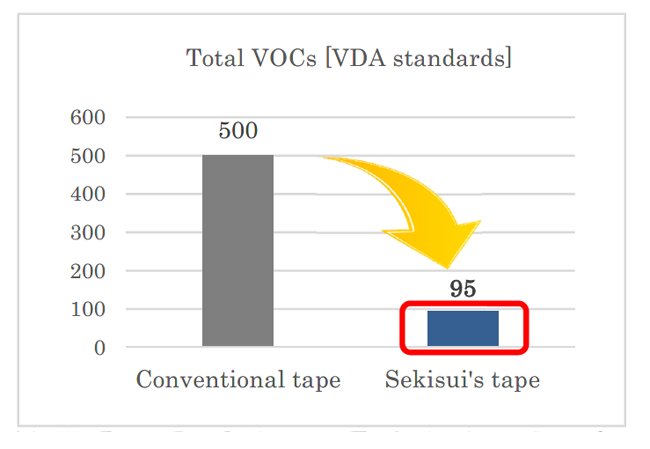

3)Low VOC tape usable as an interior material

While maintaining adhesive strength and performance, the two tapes can minimize VOCs that badly affect the human body, contributing to the creation of a comfortable environment in enclosed areas such as the inside of a car.

In the temperature range where common acrylic adhesives are not tolerated, silicone adhesives, which may contain 13 VOC substances, are often used. Our “High heat-resistant transfer tape 5503HT・5505HR” have the potential to be an alternative material.

- **VDA 278: Thermal desorption analysis of organic emissions for the characterization of non-metallic materials for automobiles, verband der automobilindustrie.

4. Future Business Development

“High heat-resistant transfer tape 5503HT・5505HR” have already been selected for use in fixing radiant heaters for EVs.

In the future, we will accelerate the development of applications in various fields, including housing and industry with the aim of achieving sales of 500 million yen in fiscal year 2025.

We will continue to develop products that meet the needs of customers and the changing times, contributing to solving social issues, and will work to be a company that is trusted more by all stakeholders, while aiming to realize both a sustainable society and the growth of our group.

* The above data are measured values, not guaranteed ones.

About SEKISUI CHEMICAL Group

Headquartered in Japan, SEKISUI CHEMICAL CO., LTD. (TSE: 4204) and its subsidiaries make up the SEKISUI CHEMICAL Group. 27,000 employees in over 200 companies throughout 21 countries and regions aim to contribute to improving the lives of the people of the world and the earth’s environment. Thanks to a history of innovation, dedication and a pioneering spirit, SEKISUI CHEMICAL now holds leading positions in its three diverse business divisions as well as top global market share in interlayer film, foam products, conductive particles and more.

Since its foundation in 1947, the SEKISUI CHEMICAL Group has dedicated itself to social and environmental contribution and is now an internationally recognized leader in sustainability and environmental initiatives, having recently been selected as one of the Global 100 most sustainable companies. SEKISUI CHEMICAL Group will continue to maintain a strong corporate presence for 100 years and beyond.

Contact Information

[Press contact]

Public Relations Department

Email: kouhou@sekisui.com

[General Public Contact]

Functional Tape Division

High Performance Plastics Company

Email: info-functional-tape@sekisui.com

Disclaimer

This press release may contain forward-looking statements. Such forward-looking statements are based on current expectations and beliefs and are subject to a number of factors and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements due to changes in global economic, business, competitive market and regulatory factors.