- Achieving world-class triple capacity / higher safety / ten times faster production speeds -

The R&D Center (Director: Satoshi Uenoyama) of Sekisui Chemical Co., Ltd. (President: Naofumi Negishi, hereinafter called "Sekisui Chemical") has developed a high-capacity film-type lithium-ion battery using a coating process that has simultaneously tripled its capacity (compared to other Sekisui Chemical products), increase its safety (as a result of standard safety testing, e.g. no problems with nail penetration tests or crush tests) and speeded up production by ten times (compared to other Sekisui Chemical products).

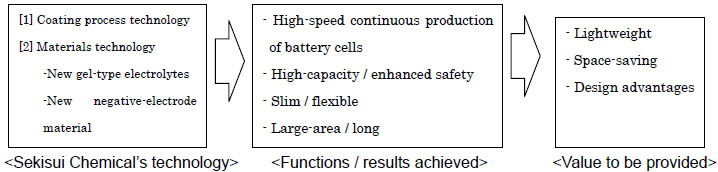

Sekisui Chemical has carried out materials technology and process technology development towards realizing the following.

|

|

(1) |

High lithium-ion conductivity (approx. ten times compared to other Sekisui Chemical products) / enhanced safety by using high-performance gel-type electrolyte*1 |

|

|

(2) |

Enhanced capacity by using high-capacity silicon negative-electrode material |

|

|

(3) |

Enhanced productivity (approx. ten times compared to other Sekisui Chemical products)by using a coating process utilizing gel-type electrolyte |

Normally solidifying liquid electrolytes is said to lead to a drastic reduction in lithium-ion conductivity. At Sekisui Chemical, we have used our original materials technology to utilize novel high-performance gel-type electrolytes with high lithium-ion conductivity (approx. ten times compared to other Sekisui Chemical products) to realize high productivity with a coating process instead of the standard vacuum infusion process.

By further adding our newly developed, original materials technology of high-capacity silicon negative-electrode material in this process, we can provide high-capacity film-type lithium-ion batteries with overwhelmingly high productivity while being flexible, slim, long and covering a large area. They make unprecedented savings in terms of space (a third the size of previous products) and can be installed in any shape or form, giving rise to a large number of applications in automobiles, houses, appliances and so on.

(Note *1: Gel-type electrolytes: electrolytes of a jelly-like substance. Because they have lower fluidity compared to liquid types, they can be used in coating)

|

|

|

|

|

|

||

|

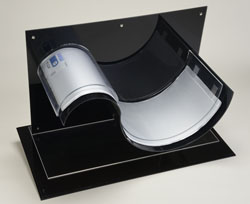

Photo 1. The next generation lithium-ion battery developed by Sekisui Chemical (sample) |

||

Part of the results of this research and development (the process technology) was achieved with support from the Advanced Technology Research Project for the Application and Commercial Use of Lithium-Ion Batteries being run by the New Energy and Industrial Technology Development Organization (NEDO).

In the future we will examine mass production with these film-type lithium-ion batteries, aiming at quickly realizing products for a variety of uses, including electric vehicles.

The achievements of this research will be announced at Eco-Products 2013 to be held at Tokyo Big Sight from December 12-14 this year.

1. Social Background to This Development

Energy consumption in Japan has generally steadily increased from the 1973 oil crisis up to FY2011. In terms of sectors, although energy-saving efforts in the industry sector resulted in a reduction to 90% consumption, the popularization of numerous electrical appliances has led to a large 240% rise in the civilian sector combining household and service sectors, and a 190% increase in the transportation sector*2. (Note *2: Source: Energy White Paper 2013 (Agency for Natural Resources and Energy))

In consideration of recent environmental problems like global warming and energy issues, there is an urgent need to strengthen efforts at energy saving and energy creation, particular importance being attached to renewable energy and clean energy utilization.

To effectively and cleanly use renewable energy, use of various energy creation devices (solar cells, wind power, etc.) simultaneously with storage battery systems, and also electric or hybrid vehicles are beginning to expand in the market. Batteries used in storage battery systems and in electric vehicles generally use lithium-ion batteries, but need further improvements.

2. The Research Process

Sekisui Chemical, which aims to be a top company for contributing to the environment, has put to use its well-honed high-performance film as an instrument to create an innovative environmental product.

The company has in particular focused its strength on energy materials and devices, spurring on R&D on battery materials and production processes for lithium-ion batteries to find solutions to the current issues of weight, space, safety and capacity.

Since FY2012 it has engaged in accelerating this research with the support of the Advanced Technology Research Project for the Application and Commercial Use of Lithium-Ion Batteries being run by the New Energy and Industrial Technology Development Organization (NEDO).

The company has made aggressive efforts in developing materials with ground-breaking high lithium-ion conductivity and processes enabling the manufacture of large-area / long battery cells which cannot be realized with existing processes.

3. Key Features of the Newly Developed High-capacity Film-type Lithium-ion Batteries

|

|

Lithium-ion batteries are a type of non-aqueous electrolyte rechargeable battery where the lithium-ion inside the electrolytes supplies the electrical conductivity. Standard models have lithium metal oxides at the positive electrode and a carbon material such as graphite at the negative electrode, and usually use electrolytic solution.

Using electrolytic solution is a barrier to ensuring the safety of the lithium-ion battery, and many research institutes are seeking to solidify the electrolytic solution, but from the perspective of performance and productivity, electrolytic solution remains the standard substance.

Sekisui Chemical, through its determined focus on using gel for electrolytes, has recently utilized new organic polymer electrolyte materials as gel-type electrolytes with high ion conductivity (approx. ten times other Sekisui Chemical products) to gain the prospect of realizing high-speed continuous production for battery cells (approx. ten times compared to other Sekisui Chemical products) and enhanced safety by using a continuous coating process rather than a vacuum infusion process. In addition, it has developed high-capacity silicon negative-electrode materials to make optimum use of this performance, realizing a high-capacity battery cell (900Wh/L).

The development of high-capacity film-type lithium-ion batteries giving practical performance while being flexible, slim, long and covering a large area has massively improved freedom in designing the shape of the final products, leading to anticipation for their use in automobiles, houses, electrical appliances and so on while gaining unprecedented lightness, space-saving (a third the size of previous products) and enhancing design through being able to be installed in any shape of form*3.

|

|

|||||||||||||||||||||||||||

4. Future Business Development

In the future Sekisui Chemical intends to further improve the batteries toward realizing actual products, beginning the provision of samples from around summer 2014, to reach the markets in FY2015 after testing and evaluation.

Disclaimer

This press release may contain forward-looking statements. Such forward-looking statements are based on current expectations and beliefs and are subject to a number of factors and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements due to changes in global economic, business, competitive market and regulatory factors.