- Total investment value approximately 20 billion yen

- The new film production line mainly focuses on wedge-shaped interlayer film for head-up displays

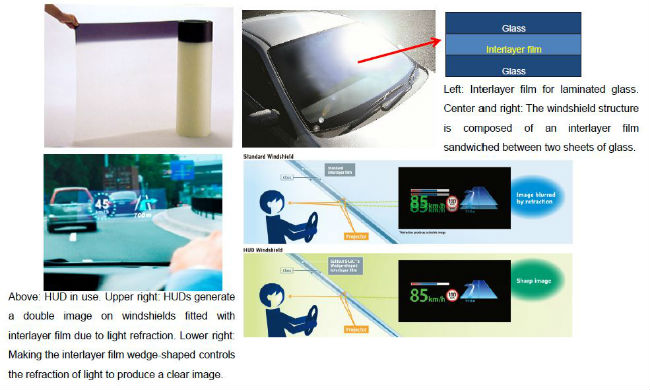

SEKISUI CHEMICAL CO., LTD. (President and Representative Director: Teiji Koge; hereinafter, “SEKISUI CHEMICAL”) has decided to expand European film production of interlayer film for laminated glass with a new film line at its plant in Roermond, and a new resin line at its plant in Geleen, both in the Netherlands. The total cost of this expansion in production capacity is approximately 20 billion yen, with operations set to commence on the new film line in the second half of fiscal 2019, and on the new resin line in the first half of fiscal 2020. With the new film production line, the company mainly plans to produce wedge-shaped interlayer film for head-up displays (HUD), which project information such as speed onto car windshields.

|

|

|

|

Film production plant (Roermond, Netherlands) |

Raw material resin plant (Geleen, Netherlands) |

1.Background and Aims

SEKISUI CHEMICAL’s High Performance Plastics Company (President: Keita Kato) globally develops and sells interlayer film for laminated glass used in automobiles and buildings. It has the world's top share in the interlayer film market for automobiles (in-house estimate for fiscal 2016).

Worldwide automobile unit production is expected to grow at around 2% per annum in the coming years, reaching 105 million units in 2021 (94 million units in 2016). In addition, the growth in demand for interlayer film for laminated glass is expected to exceed increases in automobile production, as demand spreads for applications beyond windshields to front side windows and roof windows, along with increasing demand for repairs. Furthermore, we believe that due to the expansion of demand for enhanced automobile performance in aspects such as safety, comfort, and energy efficiency, the growth rate for interlayer film with added sophisticated functions such as sound insulation, heat insulation, and HUD compatibility will remain as high as 5% or more per year. Direct-type HUDs in particular are expected to be adopted in approximately 10 million* new cars in 2020, which is about twice the number of 2017.

In view of these needs, the SEKISUI CHEMICAL Group began full-scale production of interlayer film with greater sound insulation than ordinary products at our China Plant (Suzhou City) in April 2015 and at our Mexico Plant (Morelos State) from this month. In addition to expanding the production line of wedge-shaped interlayer film for HUDs in Europe, and in consideration of enhancement of these film production lines and future growth of the interlayer film market, we also decided to expand our polyvinyl butyral (PVB) resin production line in Europe. Going forward, in order to contribute to the continued growth of the automobile industry, we will actively promote the development and sale of high performance films and expand our interlayer film business.

*In-house estimates based on some materials.

2.Overview of European bases where production capacity will be boosted

|

1) PVB Resin Plant |

|

|

(1) Location |

Chemelot SITE, Burgemeester Lemmensstreet 350, 6163JT GELEEN 3-kruiken GATE 3, The Netherlands |

|

|

|

|

(2) Products |

PVB resin |

|

(3) Production capacity increase |

1.7 times current capacity |

|

2) Film Plant |

|

|

(1) Location |

Metaalweg 5, Roermond 6045, The Netherlands |

|

(2) Products |

Interlayer film for laminated glass |

|

|

|

|

(3) Production capacity increase |

sufficient for 7 million automobiles/year |

* Both of the above plants are operated by SEKISUI S-LEC B.V. (100% subsidiary, President: Yoshio Aoshima, head office location as per 2. 2) (1) above), which manufactures and sells interlayer films.

Reference: Interlayer film for laminated glass; wedge-shaped interlayer film for HUD

|

|

Reference: SEKISUI CHEMICAL Group production bases for interlayer film and raw material (PVB resin)

Our company is developing the interlayer film business globally based on the "s-lecTM(S-LEC)" brand.

|

|

|

|

Plant name |

Location |

Operation started |

Product manufactured |

|

Film production |

Shiga Minakuchi Plan |

Koka City, Shiga Prefecture, Japan |

1960 |

Standard film, sound insulation film, heat insulation film, wedge film |

|

Mexico Plant |

Morelos State, Mexico |

1974 |

Standard and sound insulation films |

|

|

Netherlands Plant |

Roermond City, The Netherlands |

1997 |

Standard film, sound insulation film, wedge film (new film production line) |

|

|

Thailand Plant |

Rayong Province, Thailand |

2002 |

Standard and heat insulation films |

|

|

China Plant |

Suzhou City, Jiangsu Province, China |

2004 |

Standard and sound insulation films |

|

|

North America Plant |

Kentucky State, U.S. |

2007 |

Standard film, sound insulation film, wedge film |

|

|

Raw |

Shiga Minakuchi Plant |

Koka City, Shiga Prefecture, Japan |

1960 |

PVB resin |

|

Netherlands Plant |

Geleen City, The Netherlands |

2007 |

PVB resin |

Disclaimer

This press release may contain forward-looking statements. Such forward-looking statements are based on current expectations and beliefs and are subject to a number of factors and uncertainties that could cause actual results to differ materially from those expressed or implied by such statements due to changes in global economic, business, competitive market and regulatory factors.