Earthquake resistance

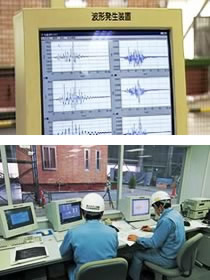

The earthquake resistance is a key point when building houses in Japan, which is frequently prone to earthquakes. We have tested Heim under various seismic waves, including waves with 1,800 gal, which is twice as strong than those observed during the Great Hanshin Awaji Earthquake. Heim demonstrated that the structure remains undamaged, even when subjected to stronger earthquakes, repeatedly occurring for days.

Full-size test

Full-size test of real residence assuming actual life

Approximately the same model building to a comfortable Parfait house, with a large opening for windows, heavily tiled external walls and a wide balcony was built for the test. Estimating the weight of furniture, 60kg/m2 loads were also added. Although full-size tests featuring the building repeatedly subject to violent vibration represent hostile conditions, we nevertheless plan to conduct tests under such conditions.

Tests under different seismic waves, such as inland and interplate earthquakes

The Great Hanshin Awaji Earthquake was known as an inland earthquake, occurring near cities with very strong instantaneous shock waves. On the other hand, the Tokai Earthquake, which is predicted to occur in the near future, may be an interplate earthquake. This type of earthquake has its hypocenter under the sea and the quake continues for longer than that of an inland earthquake, meaning the consequent damage to buildings may be greater.

We have tested Heim under various seismic waves of inland and interplate earthquakes and confirmed its safety following each seismic wave.

Tested against great shocks equivalent to earthquakes occurring within tens of thousands years

We carried out full-size tests for Heim under various seismic waves for three days. As the interplate earthquake tests, 6 seismic waves from the Miyagi Offshore Earthquake and 25 seismic waves from the predicted Tokai Earthquake were used for the tests. In four of those tests, 1,330 gal, the maximum capacity of the vibrator, was repeatedly applied to the building. For the inland earthquake tests, 18 seismic waves from the Great Hanshin Awaji Earthquake were used for the test. In eight of those tests, the seismic waves applied were greater than those of the real earthquake having occurred in the past. The greatest wave of 1,800 gal, which is 2 times greater than the figures observed in the real earthquake and the maximum capacity of the vibrator, were also applied to the building. The total number of tests was 49. Such conditions, namely the number and scale of the earthquakes, could not possibly affect any building. However, Heim demonstrated its strength, even under circumstances faced with several aftershocks coming after the main shock for example.

Heim has immeasurable earthquake resistance.

Tests were carried out under conditions approaching the limit of the testing machine system.

Scales of main tests

Unit structure

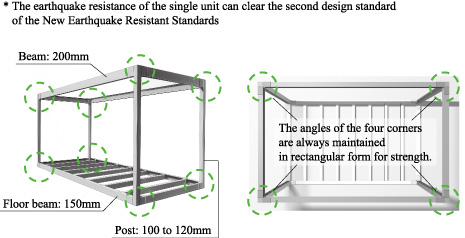

Even a single unit can withstand the force of an earthquake equivalent to the largest magnitude in centuries

When a building is exposed to shocks from an earthquake, the force is concentrated on the joints. For the Heim's unit, posts and beams are welded through joint-pieces (steel plate reinforcement) and it forms a box frame structure* with integrated posts and beams. Unlike an ordinary frame structure, where the posts and beams are jointed with bolts, this is a very strong structural unit with no weak areas. In addition, the posts and beams are always made to form rectangles, in order to minimize the deformation and damage of the building incurred.

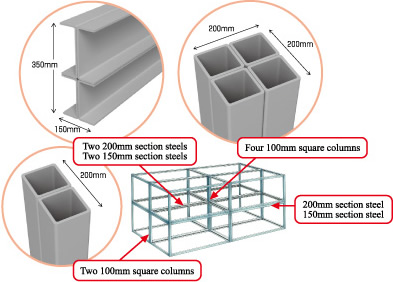

Combined units become even stronger, with jointed 2 or 4 posts and beams

The strength of a post and beam depends not on the thickness but on the sectional area. When a Heim's strong single unit is connected to other units, the joints of the units become stronger, with 2 or 4 posts and beams forming large sectional areas. In particular, the floor beams of the second floor, which are exposed to the maximum shock from the earthquake, form sectional areas as large as 350mm x 150mm. This unit structure will be able to cope with the seismic intensity from the largest earthquake.

Units are firmly connected with high-tension bolts usable for bridgework

Heim comprises several combined units, between which the joints are firmly connected via high-tension bolts. These high-tension bolts, 16mm in diameter, with semi-permanent strength and usually used for bridgework, are used to connect units vertically. Eight bolts, each of which bears 1 ton (9.8kn) of shear force, connect units horizontally, while four anchor-bolts, each bearing 2.2 (21.6kn) ~ 12.2 tons (119.6kn) shear force connect the entire unit to its foundations. Every unit and set of foundations are integrated into a single strong structure without any weak area.

An anchor bolt to firmly connect the unit and foundation

Every bolt is managed for the torque to be fixed as calculated in order to exert maximum strength.

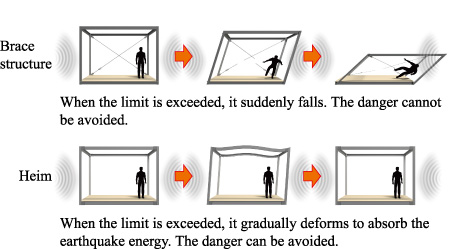

The flexibility of the box frame structure and external walls that absorb earthquake energy prevent sudden destruction, even when exposed to the largest seismic motion.

Heim's box frame structure, like a high-rise building, absorbs earthquake energy by bending slightly. The external walls also have a structure capable of absorbing the earthquake energy. With this box frame structure and the external walls, the acceleration (response acceleration) to which the building is exposed diminishes compared to that of a brace structure building, which resists the acceleration by its own strength.

When the box frame structure building is exposed to the maximum earthquake energy, the resulting acceleration is smaller, meaning it avoids sudden destruction, unlike buildings using their own strength to resist this energy. Focusing on potentially falling furniture and remaining inside the building until the quake stops may therefore be safer than evacuating outside.

External wall

A unique external wall designed to absorb quakes

Each external wall material slightly deforms, synchronizing to the quake affecting the building structure, and the entire external walls absorb the seismic shock. Meanwhile, the gasket masonry joints method is adopted for the joint external walls and these gaskets also function as shock-absorbing material. When the building structure reverts to its normal shape after being subjected to the violent stresses of a great earthquake, the structural design also allows the external walls and gasket to return to normal conditions. There is little fear of the external walls cracking or falling.

The outer wall materials are fixed between posts with special clasps called studs, which are designed to absorb the energy from seismic shocks. The effect of the quake is thus also decreased by the energy absorbing effects.

Using lightweight members to control the shock of the building

Seismic motion comprises various elements, including amplitude, period and velocity. In particular, acceleration (gal) is closely related to the force exerted on a building. The relationship between the acceleration and the force to which a building is exposed can be expressed as: Force added to building = mass of building x acceleration. The larger the mass becomes, the stronger the shock becomes. Usually, external walls with tiles are rather heavy, but we use our own developed lightweight and flexible SFC boards (cement rich surface and wooden chip rich inside). In addition, we also use our noise reduction floor, developed in-house without ALC or concrete boards and bruck roofing material that is half the weight of Japanese roof tiles. The use of such lightweight members to reduce damage is incorporated into every part of Heim.

Full size tests using real residences revealed no damage or falling tiles.

It is estimated that many tiles used for ordinary houses will be prone to damage or falling at seismic intensities of 6 or lower. However, each one of the Heim external wall tiles is affixed to the strong and flexible SFC boards using elastic adhesives. Furthermore, adhering work is carried out in factory with carefully controlled humidity. Consequently, the strength and stability of the adherence are far superior to those applicable to on-site work. No damage or falling tiles were observed during full size tests involving exposure to forces 2 times stronger than the shocks during the Great Hanshin Awaji Earthquake

Foundation

We use a mat foundation that bears a load over its whole surface and is a structure spreading the seismic force to the ground

The mat foundation has attracted attention since the Great Hanshin Awaji Earthquake and is used in Heim as one of the standard features. Unlike a continuous footing system, that bears load via a line, via which seismic force is channeled into the ground, the mat foundation bears load over its whole surface and seismic force flows from the surface into the ground to protect the building on its foundation. The mat foundation thus has superior earthquake resistance as well as functions to control the liquefaction phenomenon and differential ground settlement, helping to enhance the building safety.

The solid foundation scatters force from the construction load and it is effective for ground with a high soil bearing capacity (less than 50kn/m2)

Liquefaction means the settlement of ground that occurs when water-containing soils are parted by the quake, float in water, then sink.

The differential settlement means a phenomenon whereby the ground cannot bear the construction load and differentially sinks, consequently causing the construction to incline.

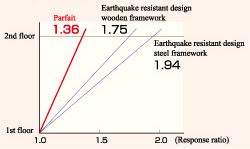

Heim demonstrated the ability to reduce quake impact during full size tests

The figure for acceleration (gal) shows the magnitude of ground motion caused by the earthquake. The response ratio, meanwhile, shows the value indicating how many times the acceleration to the foundation is magnified and reaches each floor. The smaller the value, the more the building is stable and further the damage is minimized. The response ratio of Parfait was measured as a ratio of 1.36 on the second floor during full size tests. This value is much smaller than ordinary houses built using conventional buildings. The stability and strength of Heim to resist earthquakes are therefore verified in its design.

Heim demonstrated the ability to reduce quake impact during full size tests

Meanwhile, Members of units contributing to the load bearing and durability qualities of the building are manufactured with a high degree of accuracy by using the latest high-tech machine tools. The level of errors made during manual work performed by skilled on-site workers is generally estimated as around 5%. In our Heim production plants, however, the use of all the members of units and parts is specified, pre-inspected members and parts are always used and the number of orders placed from building sites are strictly limited. In addition, specialized inspectors thoroughly inspect 250 items. Thus we implement perfect quality control for manufacturing and building Heim, to ensure it is designed without variation or errors.